Description

Products Description

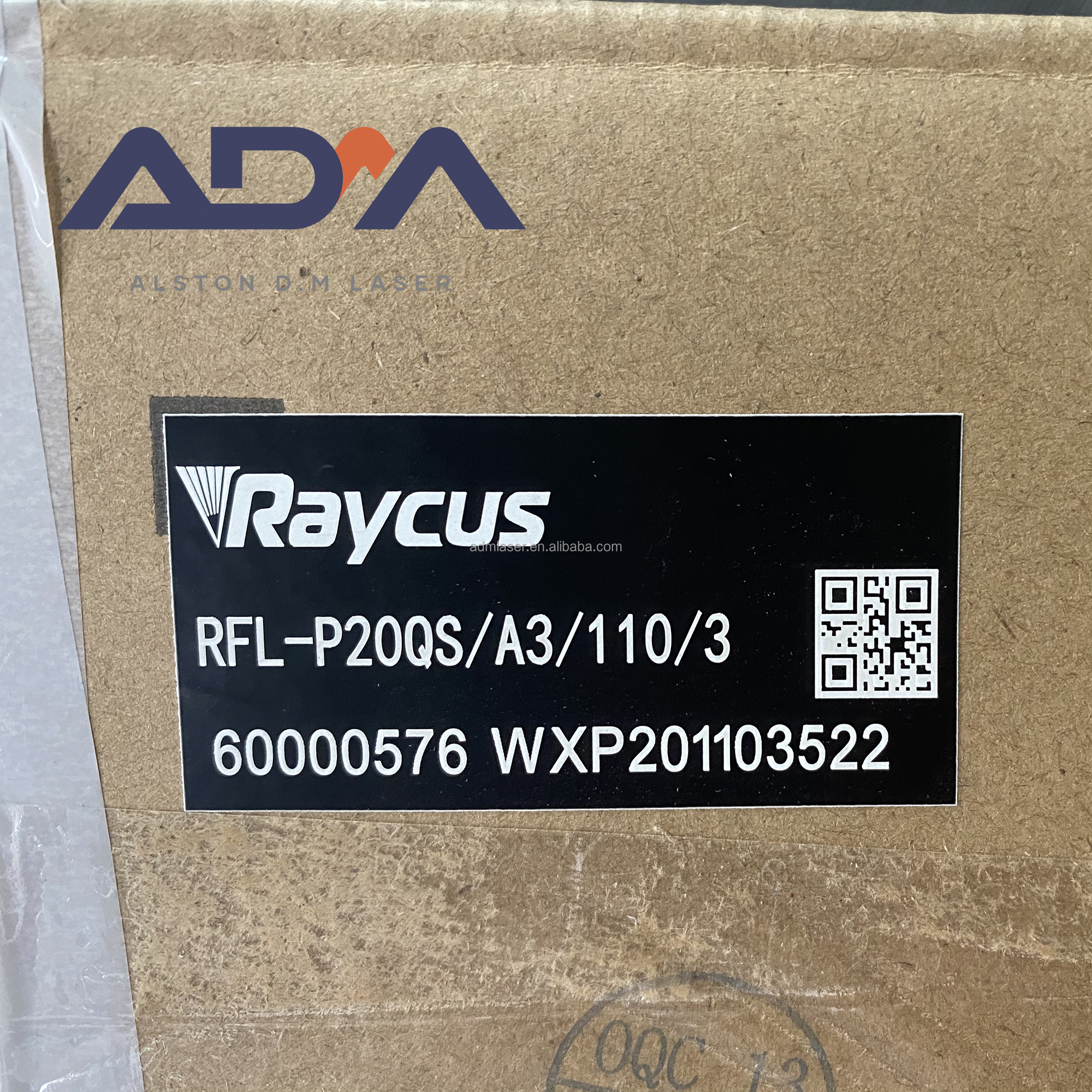

1.1. Product description

Raycus pulsed laser is an ideal high power laser source with high speed and high efficiency. It is

specially designed for industrial laser making system and other applications.

Compared with traditional lasers, pulsed laser has some unique advantages in increasing the

conversion efficiency of the pump light 10 times higher. Its low power consumption and

automotive design make it appropriate for operating both in and outside the lab. Besides, it is

exquisite and convenient for its independence in placement, free time in using and facility in

connecting to equipment directly.

The device can emit 1060~1085nm wavelength pulsed light under the control of industrial

laser’s standard interface driven by 24VDC power source.

Raycus pulsed laser is an ideal high power laser source with high speed and high efficiency. It is

specially designed for industrial laser making system and other applications.

Compared with traditional lasers, pulsed laser has some unique advantages in increasing the

conversion efficiency of the pump light 10 times higher. Its low power consumption and

automotive design make it appropriate for operating both in and outside the lab. Besides, it is

exquisite and convenient for its independence in placement, free time in using and facility in

connecting to equipment directly.

The device can emit 1060~1085nm wavelength pulsed light under the control of industrial

laser’s standard interface driven by 24VDC power source.

1.2. Environmental requirements and cautions

Pulsed laser should be driven by 24VDC±1V power source.

1) Caution: Make sure the corresponding wires of the device are properly grounded.

2) All the maintenance to the device should only be done by Raycus, because there is no

replacement or accessory provided with the device. Please do not try to damage the labels or

open the cover in order to prevent against electric shock, or the warranty will be invalid.

3) The output head of the product is connected with an optical cable. Please be careful handling

the output head. Avoid dirt and any other contaminations. Please use the specialized lens

paper when cleaning the lens. Please lid the laser with protective cover of the light isolator to

be against dirt only when the laser is not installed in the device or not in working.

4) If the operating the device fails to follow this instruction, the protective function will be

weakened. Therefore, it should be used under normal conditions.

5) Do not install the collimating device into the output head when the laser device is in working

Pulsed laser should be driven by 24VDC±1V power source.

1) Caution: Make sure the corresponding wires of the device are properly grounded.

2) All the maintenance to the device should only be done by Raycus, because there is no

replacement or accessory provided with the device. Please do not try to damage the labels or

open the cover in order to prevent against electric shock, or the warranty will be invalid.

3) The output head of the product is connected with an optical cable. Please be careful handling

the output head. Avoid dirt and any other contaminations. Please use the specialized lens

paper when cleaning the lens. Please lid the laser with protective cover of the light isolator to

be against dirt only when the laser is not installed in the device or not in working.

4) If the operating the device fails to follow this instruction, the protective function will be

weakened. Therefore, it should be used under normal conditions.

5) Do not install the collimating device into the output head when the laser device is in working

6) The device has three cooling fans at the rear panel to dissipate heat. In order to guarantee

enough airflow to help giving heat off, there must be a space of at least 10 cm’s width for

airflow in front and rear side of the device. As the cooling fans are working at blow condition,

if laser is mounted in a cabinet with fans, the direction should be same as laser’s fans.

7) Do not look into the output head of the device directly. Please do wear appropriate laser

safety eyewear during the time when operating the device.

8) Make sure the pulse repetition rate higher than 20 kHz.

9) For the longest time without pulse is only 100 us. If there is no pulse output, please stop

marking at once, to avoid further damage of the device.

10) Power source sudden interruption will do great harm to the laser device. Please make sure

the power supply works continuously

enough airflow to help giving heat off, there must be a space of at least 10 cm’s width for

airflow in front and rear side of the device. As the cooling fans are working at blow condition,

if laser is mounted in a cabinet with fans, the direction should be same as laser’s fans.

7) Do not look into the output head of the device directly. Please do wear appropriate laser

safety eyewear during the time when operating the device.

8) Make sure the pulse repetition rate higher than 20 kHz.

9) For the longest time without pulse is only 100 us. If there is no pulse output, please stop

marking at once, to avoid further damage of the device.

10) Power source sudden interruption will do great harm to the laser device. Please make sure

the power supply works continuously

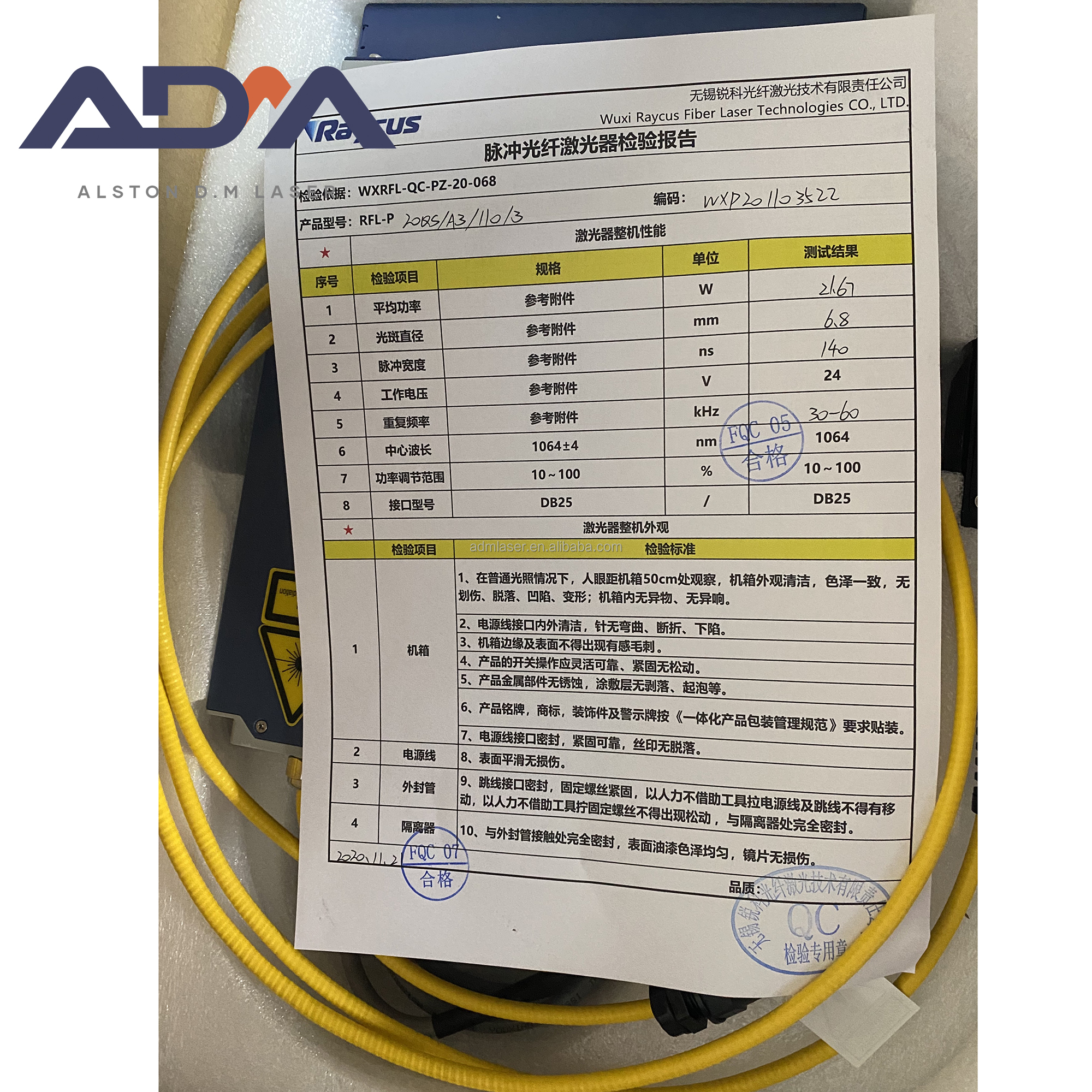

1.3. Specifications

10Q、20QE、20Q、30Q、50QB pulsed fiber laser specifications

Features

Compared with traditional lasers, Raycus CW fiber laser has higher efficiency electric-optical conversion, lower power consumption and excellent beam quality. The fiber laser is compact and ready to use. It can be used as a stand-alone unit or easily inserted into user’s apparatus.

Main Features:

Excellent beam quality

High quality fiber output

High Power Stability

Continuously tunable output power, quick switching response

Maintenance free operation

High wall plug efficiency

Convenient control interface

High frequency modulation

Applications:

Cutting, Welding

3D Printing

Scientific research

Main Features:

Excellent beam quality

High quality fiber output

High Power Stability

Continuously tunable output power, quick switching response

Maintenance free operation

High wall plug efficiency

Convenient control interface

High frequency modulation

Applications:

Cutting, Welding

3D Printing

Scientific research

Reviews

There are no reviews yet.