Description

- Brand Name: YUPEI

- Origin: Mainland China

- Is Smart Device: NO

- Output Power: 650W

- Dimensions: 25*12*8CM

- Input Voltagle: 220V/110V

- Output Temperature: 0~50

- Temperature Stability: Refer to SPEC

- Certification: None

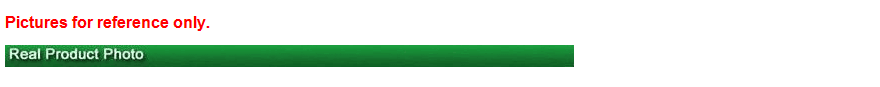

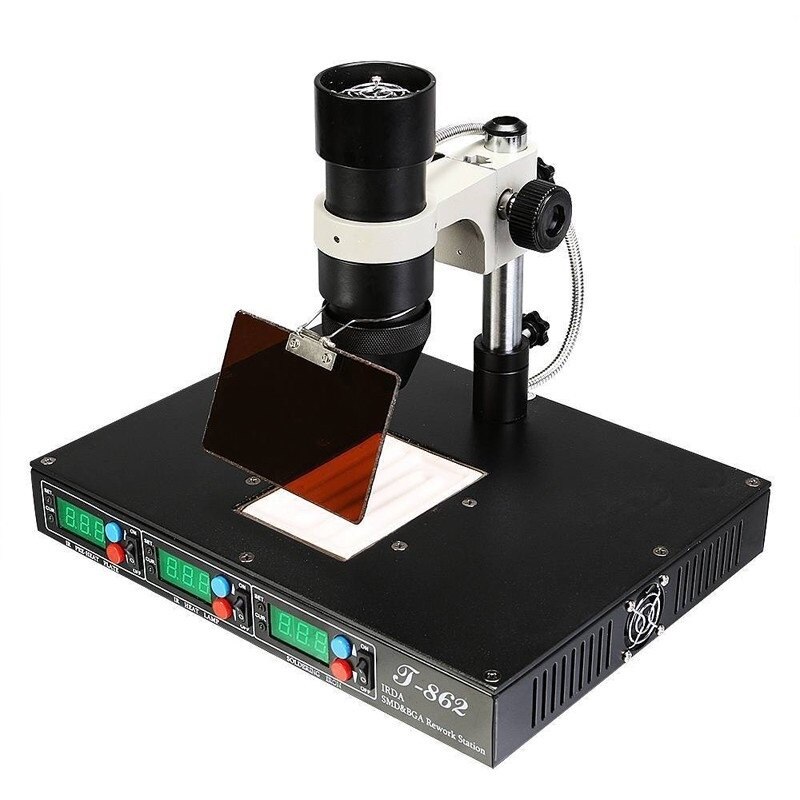

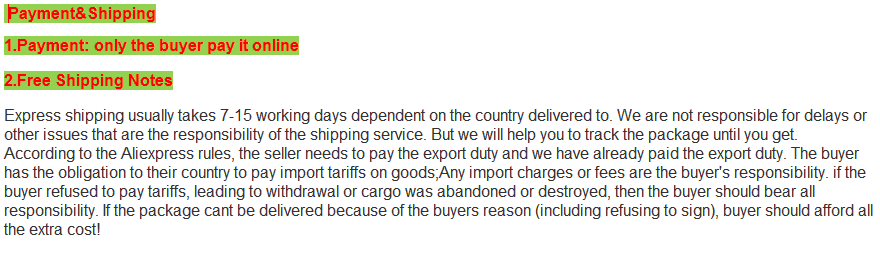

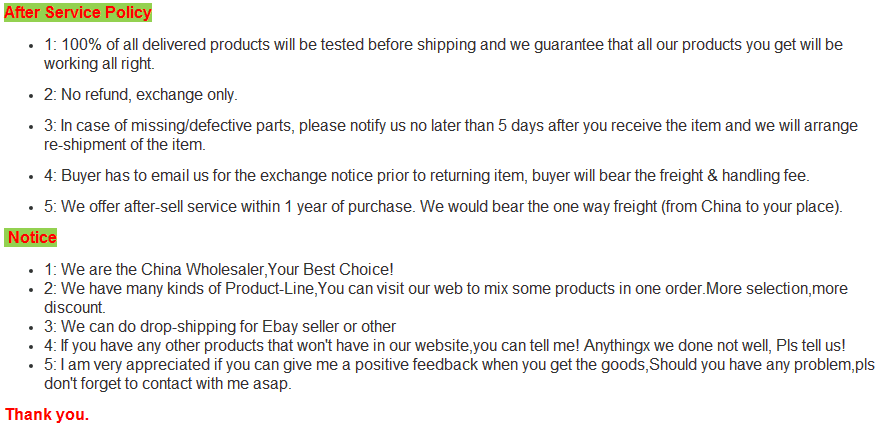

- Model Number: T-862

- Usage: SMD Soldering Rewor

- Preheating area: 80mm*120mm

- Welding area: 25*25mm

PUHUI T-862 Infrared SMD Soldering Rework Station Soldering Welder Mobile Phone

Motherboard Desoldering Station Maintenance

Parameter:

Working voltage : AC220

Output power 650W

Temperature 100°C – 350°C

Preheating area 80mm*120mm

Heating Infrared lamp heating

Lamp diameter size 15mm

Characters:

Can suitable for all of the component,especially Micro BGA component.

1. Adopt infrared weld technology which independent exploration.

2. Use infrared heat,it is easy to cut through,heat proportion piercing tradition weld machine with sirocco.

3. Easily operate.Just need one day training.Can operation this machine.

4. No need weld tools,it can weld all the component of 15×15-35x35mm.

5. This machine has 650W heating system.widely to 80x120mm.

6. Infrared heating no have sirocco flow. Don’t impact perimeter scomponent. Can suitable for all of the component,especially Micro BGA component.

Operation method:

(1). Locate, choose and attach the appropriate lens:

The usable of the lenses diameter are 28mm, 38mm, 48mm.

(2)When the area of the chips is below 15mm*15mm, please choose the IR-lamp temperature about 160-240, and choose the lens which D=28mm to avoid destroying other places, usually it will take you about 20-40 seconds.

(3)When the area of the chips is between 15mm*15mm and 30mm*30mm, please choose the IR-lamp temperature about 240-320, and choose the lens which D=38mm to avoid destroying other places, usually it will take you about 30-60 seconds.

(4)When the area of the chips is above 30mm*30mm, please choose the IR-lamp temperature 350(Attention: you should turn on the pre-heat dish first, and set-up the temperature about 150-200,wait 3-5 minutes to allow the temperature steady on the set-up temperature),and choose the lens which D=48mmto avoid destroying other places, and keep the lamp body direct light. You should control the time carefully to avoid burning the chips.