Description

RoHS is a compulsory standards set by the eu legislation, it is the full name of “about limit use of certain harmful components in electrical and electronic equipment directive(Restriction of Hazardous Substances).This standard has been started on July 1, 2006 formally implemented, it is mainly used for electrical product specification material and craft standard, make it more conducive to human health and environmental protection.The purpose of this standard is to eliminate electrical electronic products in the lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PCBS) and polybrominated diphenyl ether, a total of 6 substances, and the key specifies the amount of lead that the should not exceed 0.1%.

The detection method of toxic and harmful substances in electronic products(hereinafter referred to as the test method, the standard number of SJ/T 11365-11365) of harmful elements in RoHS requirements given the limited testing method.X-ray fluorescence spectrometry (XRF) as one of the most fast and convenient method is formulated for rapid screening method.Using X-ray fluorescence spectrometry (XRF) of lead (Pb), mercury (Hg), cadmium (Cd), chromium (Cr) and the corresponding standards of bromine (Br) five elements for precise test sample.But only based on the principle of XRF element content, that is to say if this screening test for chromium (Cr) or the content of bromine (Br), even if they are overweight, also does not represent the harmful substances (Cr VI) and flame retardant PBB and PBDE), the test results (containing) only contain the corresponding necessary conditions rather than sufficient conditions for hazardous substances.This is limit without these two kinds of harmful substances in the table is not qualified limit value judgment.

* High resolution, high definition camera, convenient operation

* Nondestructive, rapid and accurate detection, human interface

* Heart of Europe,all core technologies from Europe and America

* Easy to use, one key operation, each element ROHS analysis results

* Test coating samples of innovative features

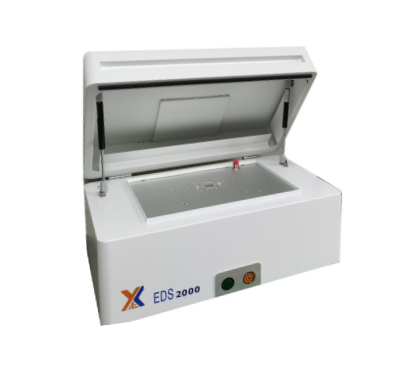

* The structure compact, appearance is very beautiful, suitable for placed on display room

* Press the button within seconds, can get the accurate results of the chemical composition of samples

* The use of PCS and software, can rapid conveniently make sample inspection result certificate

* Camera and cabin lighting system, real-time view sample testing, accomplish know fairly well

* Analyzer test data can be download and upload network detection results is easy to view and share

* And reliable power flow and short circuit protection, reliable to ensure the safety of the user

* Automatic test system of control, reliable guarantee of customers to use

|

Analysis |

1 PPM to 100% |

|

Precision RSD |

0.01% ~ 0.05% |

|

Test samples of physical |

state of solid, liquid and powder |

|

Light tube voltage |

5 kv ~ 50 kv/optional import light tube |

|

High voltage power supply |

0 ~ 50 kv Spellman (USA) |

|

Light control current |

0 mu A ~ 1000 mu A |

|

Camera |

high-definition cameras |

|

Detector |

Si Pin/SDD (optional) |

|

Resolution |

Si – pin145 + 5 ev /SDD135 + 5 ev (USA) |

|

Multichannel analyzer |

DMCP |

|

Test time |

200SEC ~ 600SEC |

|

ROHS analysis common elements |

Pb, Hg, Br, Cr, Cd, Ba, Sb, As..Etc. |

|

Analysis software |

FP qualitative quantitative analysis software |

|

Dimensions |

615*418*315(mm) |

|

Weight |

45kg |

|

Power Requirement |

Provided 220 VAC ,50 Hz to 60 Hz,,300watts power supply |

|

Excitation Source |

50W, 50kV, 1000μA (max) |

|

Detector |

Si-PiN diode detectorSi Drift detector |

|

Environmental Temp Range |

-10°C to 50 °C |

Reviews

There are no reviews yet.