Description

- Origin: Mainland China

- Rated Duty Cycle: 220V/110V 50/60Hz

- Certification: CE

- Weight: 9

- Is Smart Device: NO

- Model Number: LY-150A

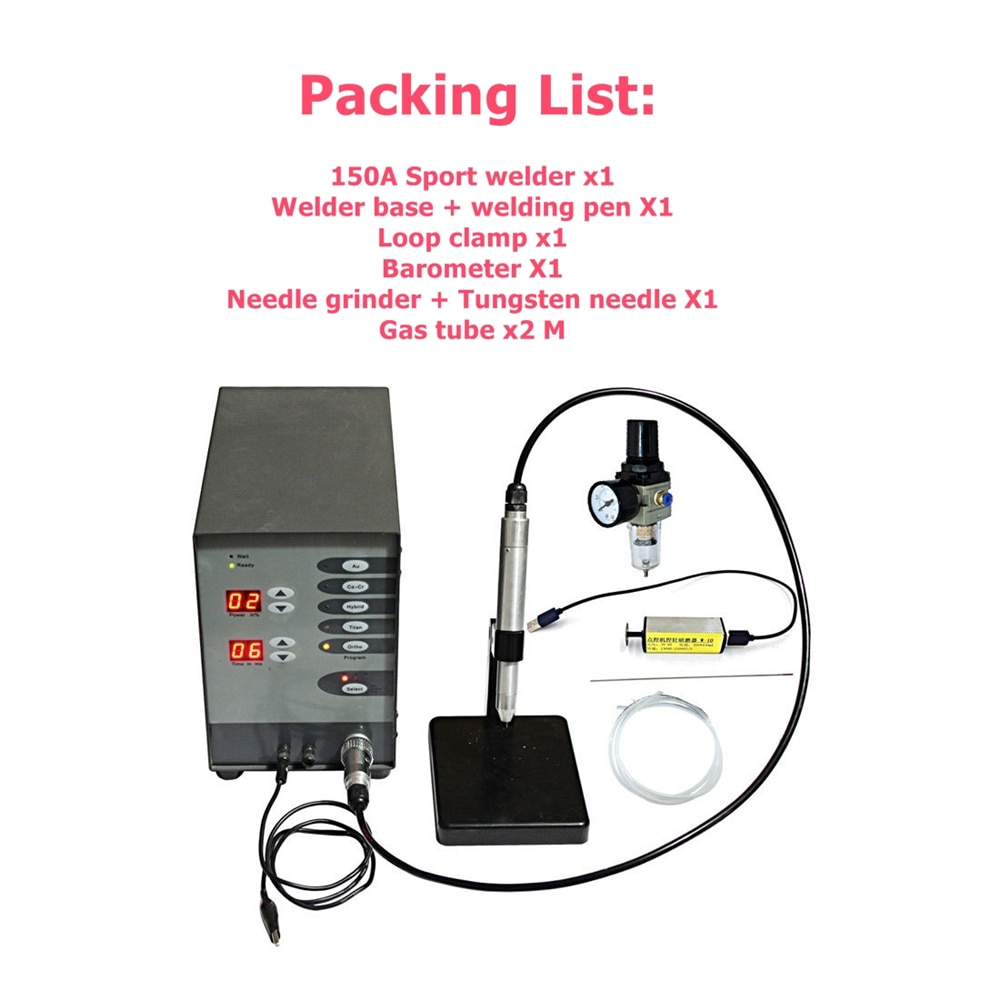

LY 150A Big Power 100W Pulse Argon Arc Spot Welder Machine Laser Welding

Stainless Steel Weld Station Compatible

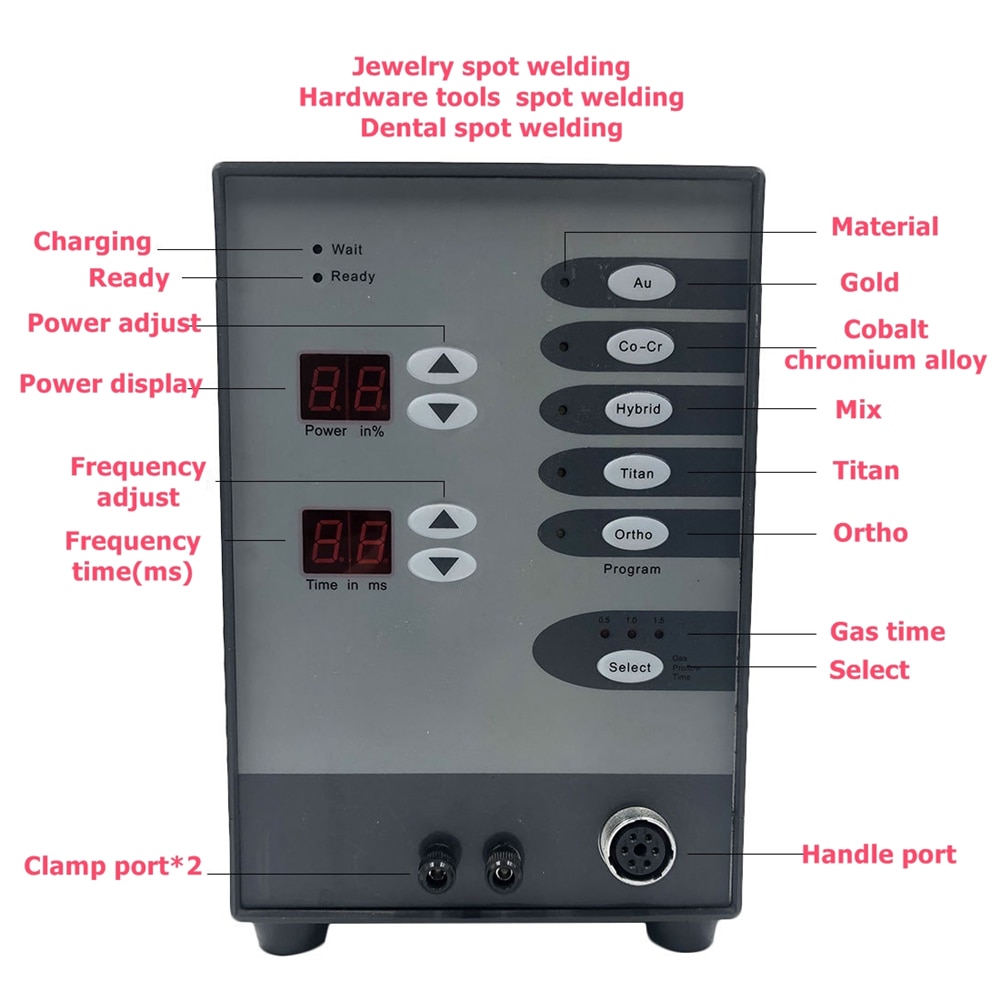

Argon Arc Spot Welder for Jewelry & Dental This unit is suitable for all types of dental welding jobs, jewelry welding works, for both new restorations and repairs. The range of application equals at least to a laser welding unit, and cost of the equipment and operations is much cheaper than a laser welding unit. Features: Argon-arc Spot Welders includes five preset basic programs for gold (Au), cobalt chrome (co-cr), hybrid-welding (such as precious to non precious), titanium (Ti) and orthodontics.Besides its features compact size, safe and stable system, easy operations, low noise and maintenance. It requires minimum working space, and the adjustable power and pulse settings allows adjustment of penetration depth and welding spot diameter. This unit will switch to Ortho mode if there is no operations within 5 minutes to prevent any damage to the workpiece. It’s great for jewelry and dental welding.

(RE: Argon is not necessary to make spot welding, base on target materials.)

Technical Data:

Model:LY-150A

Power Supply: 220V/110V 50/60Hz

Power Consumption: 100W

Degree of protection: IP21

Gas supply pressure: 0.1Mpa up

Welding voltage: 40V

Welding currency: 50A-150A

Welding time: 3ms–30ms

Max. welding frequency: 1Hz Max.

Argon consumption: 5L/min

Dimensions: 300mm*135mm*235cm;

Package size:410mm*305mm*260mm

Weight: about 8.5kg.

In order to avoid electric shock, fire and dangerous accident when using electrical equipment, be sure to pay attention to following basic safety measures.

1. Before using the instrument, please read this manual and precautions. Placing this manual near the instrument for convenient view.

2. Please keep the electrical equipment away from children and absolutely forbid children to play this electrical equipment, spare parts and other cables.

3. The operating of the equipment should maintain good ventilation and lighting, do not work in a humid and dusty environment thus to avoid accidents by abnormal environment.

4. Never let any liquid enter the instrument.

5. There will be a strong arc light when operating, irrelevant personnel should away from the work site for avoiding damage the eyes.

6. Do not use cable to drag equipment. Cables should be away from heat, oil and other sharp objects, so as not to damage the cable.

7. You must completely cut off the power before clean the equipment and open the case.

8. This machine with compact and reasonable structure does not need special and tedious maintenance. Paying attention to the cleaning of the instrument, especially the microscope. Not clean the attachments will seriously affect the observation of objects.

9.The instrument should be covered with a dust cover in non-working status.

10. For your security, please use the correct fittings.

Attention: The machine did not include the microscope, and you can also work without microscope