Description

Buying trips

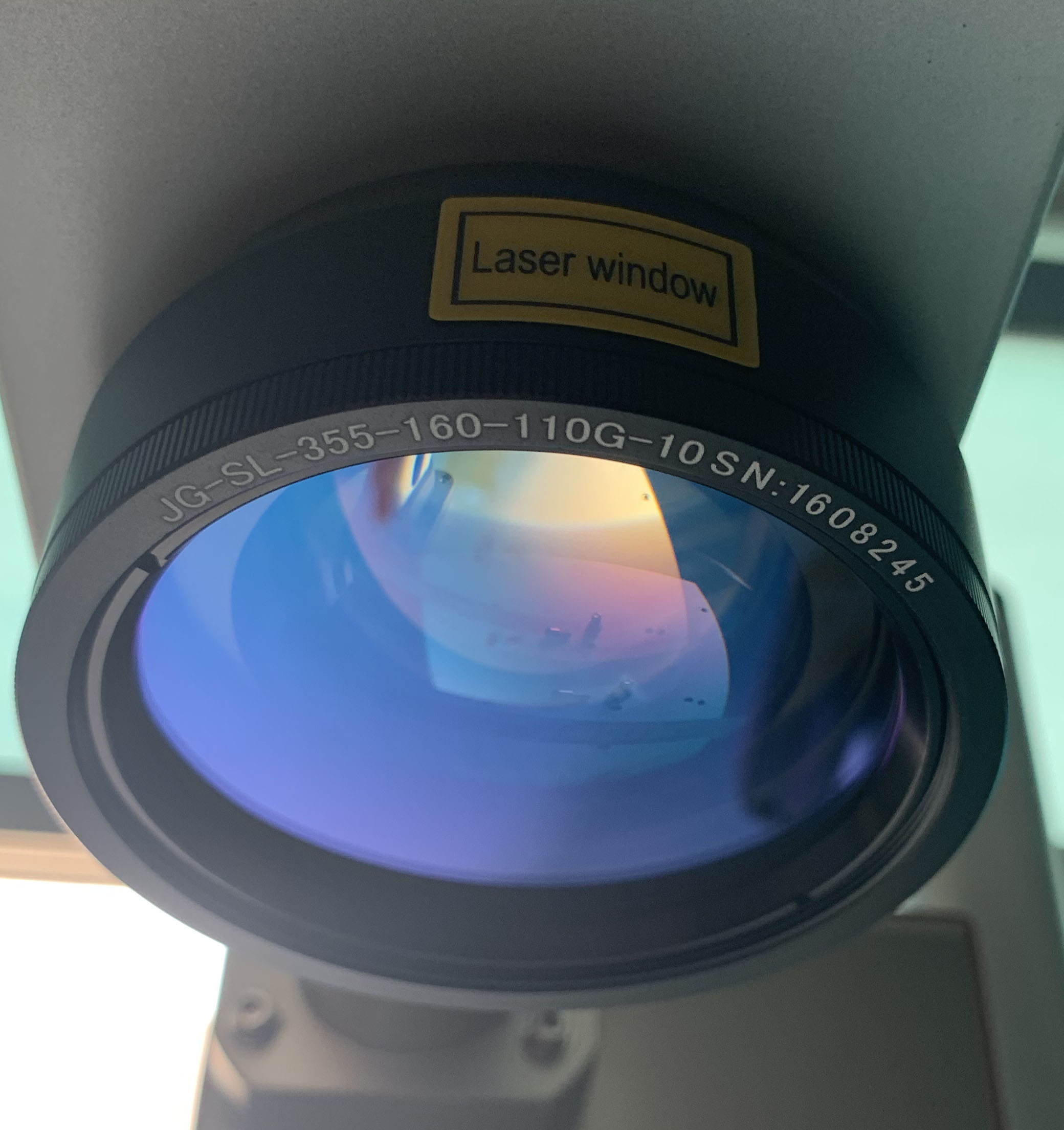

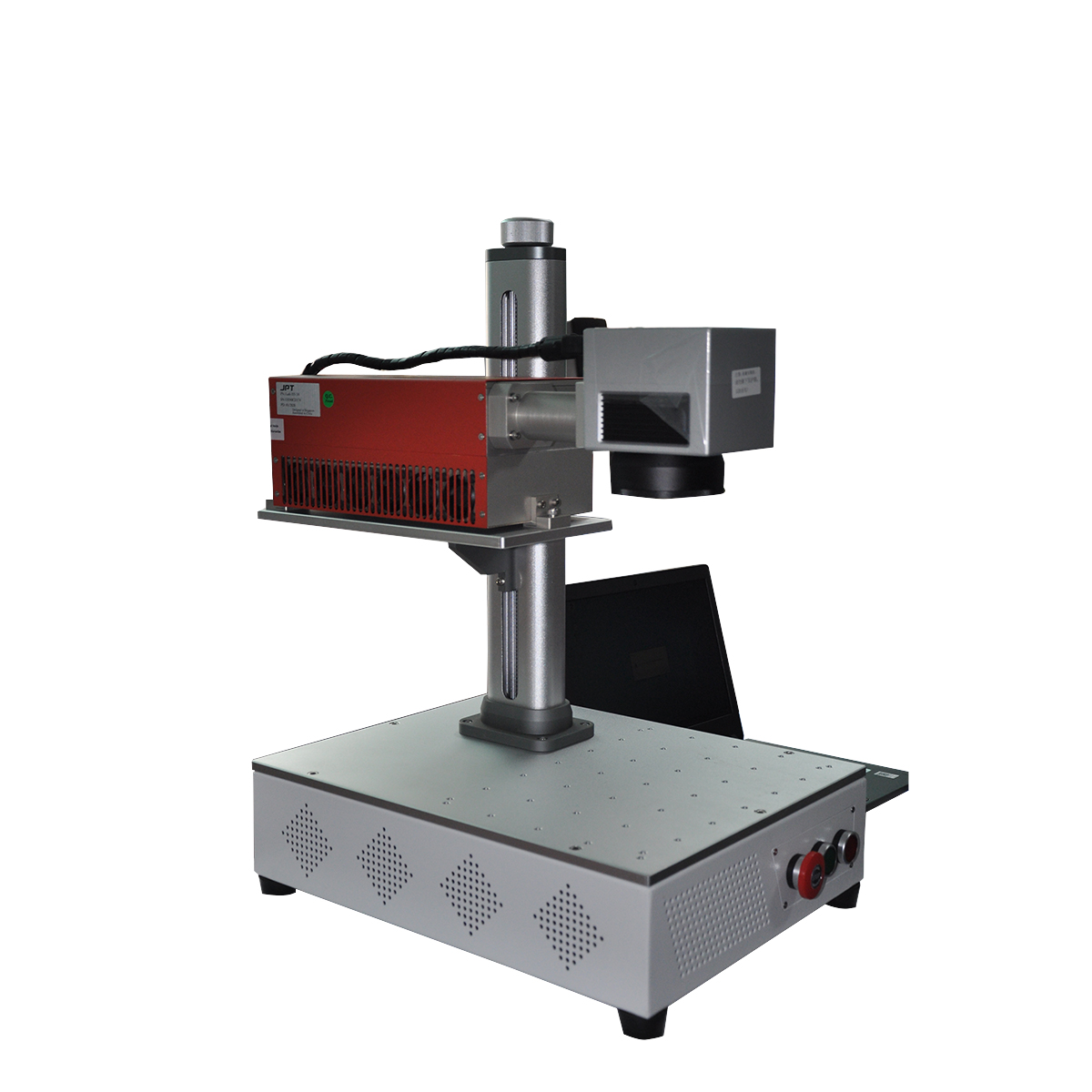

Ultraviolet laser marking machine belongs to a series of laser processing technology. It uses 355nm UV laser as the light source.

The machine uses third-order intracavity frequency doubling technology to compare with infrared laser (pulsed fiber laser), 355 ultraviolet focusing spot. Small, can greatly reduce the mechanical deformation of the material and has little influence on the processing heat, because it is mainly used for superfine marking, engraving, cutting and the like.

It is especially suitable for applications such as marking of food and pharmaceutical packaging materials, micropores, high-speed division of glass materials, and complex graphic cutting of wafer wafers.

Main features of UV laser marking machine:

Laser (light source): 355 nm UV laser Air-cooled device, small size, 20,000 hours maintenance-free (theoretical 20,000 hours of service life). More than 5W power requires water cooling, distilled water or pure water.

The focused spot is extremely small, and the processing heat affected zone is small (cold light), making the material

heat-receiving area smaller. Not susceptible to heat deformation, ultra-fine marking, special material marking.

Low cost of use, better beam quality, high efficiency, low power consumption, more energy saving and environmental protection.

Can be applied to high-end market, ultra-fine marking environment, cosmetics, pharmaceuticals, LCD liquid crystal, electronic components, communication equipment, food and medicine packaging, glass division, electronic components, metal jewelry marking.

removal, deep carving, fine micro machining, anodizing, oxygen-permeable conductive surface treatment And other applications;

Main applications: film etching, glass marking, material micro machining, wafer cutting, laser rapid prototyping, etc.

1. Machinery industry: hardware tools, clutches, bearings, pistons, piston rings, steel pipes, steel plates, gears, sensors,

shafts, etc.;

2, electronic components: such as capacitors, inductors, circuit boards, integrated circuits, automotive oil system, nylon, cable and wire, keyboard, etc.;

3. Instrumentation: control panel, measuring instrument, medical equipment, aviation parts, etc.;

4, household appliances, lamps, product packaging, stationery, brand-name panels, label signs, cosmetics, color paper, various paint products, cigarettes, handicrafts, etc.;

5, tableware, food, gold, jewelry, handicrafts, ceramics, building materials, sanitary ware, office supplies, etc.;

|

Model

|

TY-MUP-A3

|

|

Central wavelength

|

355nm

|

|

Polarization

|

Random

|

|

Output power

|

3w

|

|

Beam quality

|

<1.7 square meter

|

|

Facular diameter

|

7~9mm

|

|

Power stability

|

<5%

|

|

Frequency adjusting range

|

5~100%

|

|

operating voltage

|

100~240VAC

|

|

Fiber Length

|

1.5m

|

|

Cooling mode

|

forced air

|

|

Operation temperature

|

0~35℃

|

|

Operation humidity

|

10~95

|

|

Gross weight

|

70kg

|

|

marking format support

|

JPG PNG PLT DXF BMP

|

Reviews

There are no reviews yet.