Description

- Model Number: BCX

- Type: Other

- Usage: Commercial Manufacture

- is_customized: Yes

hot sale ND YAG DPSS 850nm BCX Diode Module for Laser Marking/Engraving/Cutting

Product description

The Diode Pumped Laser Module incorporates a Nd:YAG laser rod that is efficiently pumped by a radial array of long life laser diode bars, and delivers excellent gain uniformity and lensing performance. It is ideally suited for multimode applications such as laser marking, and can also provide high beam quality for more precise micro-machining and scientific applications.

The laser module is driven by low voltage electronics. Cooling of the laser is accomplished with a simple recirculating water chiller running on filtered water, eliminating the need for deionized water systems.

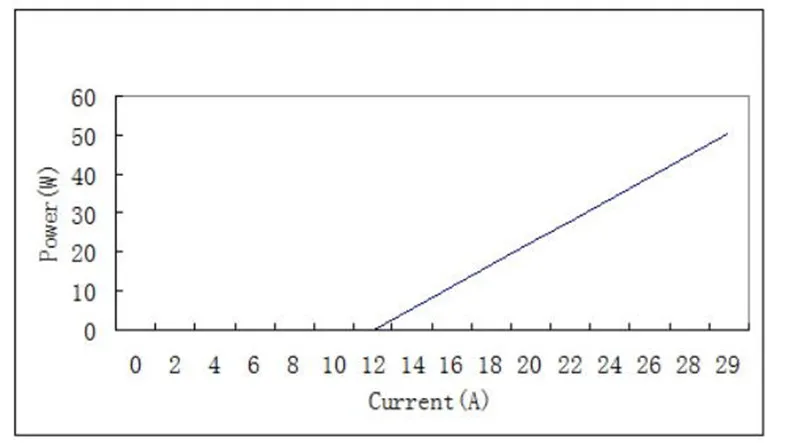

Typical Performance Curves

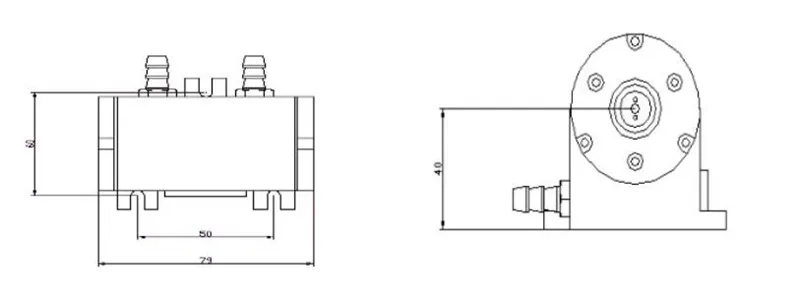

Mechanical Dimensions

Advantages of our Diode Module

I. High output power

II. Stable working condition

III. Reliable

IV. Efficient

V. Compact

VI. 10000 hours long lifetime

VII. Easy to operate

Technical Parameters

|

CW Output Power |

75W |

|

Threshold Current |

11A |

|

Operating Current |

29A |

|

Forward Voltage |

≤18V |

|

Center Wavelength |

1064nm |

|

The length of the YAG rod |

65mm |

|

The Diameter of the YAG rod |

3mm |

|

YAG Terminal |

Flat/AR at 1064nm/YAG doped 1% |

|

Weight |

≤1.5kg |

|

Recommend Case Temperature of chiller |

19-23°C |

|

Temperature Range (Storage) |

5°C~ 70°C |

Company introduction

Packing&delivery&service

How to Order?

1. Consult: we will recommend the most suitable machines to you after being informed by your requirements, such as the material you want to engrave or cut, the max size of the material( Length x Width x Thickness);

2. Quotation: We will supply you with our detail quotation according to our consulted machines, with the best quality and most competitive price;

3. Process Evaluation: Both sides carefully evaluate and discuss all the details(including technical parameters, specifications and business terms) of the order to exclude any misunderstanding;

4. Placing Order: If without any doubt, we will send you the PI( Proforma Invoice), and then both sides will sign a sales contract;We also accept the payment way of T/T.

5. Production: We will arrange the production as soon as receiving your signed sales contract and advance payment. The latest news about production will be updated and informed to the buyer during the production;

6. Quality Control: The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory;

7. Delivery: We will arrange the delivery as the terms we both agreed with and after the confirmation by the buyer;

8. Custom Clearance: We will supply and deliver all the necessary shipping documents to the buyer and ensure a smooth customs clearance.

ncerns and frustrations you might have, and will try our best to solve the problem.

Contact us

Related Products

Reviews

There are no reviews yet.