Description

a,a:hover,a:active,a:visited {color:#0d93d7 !important}

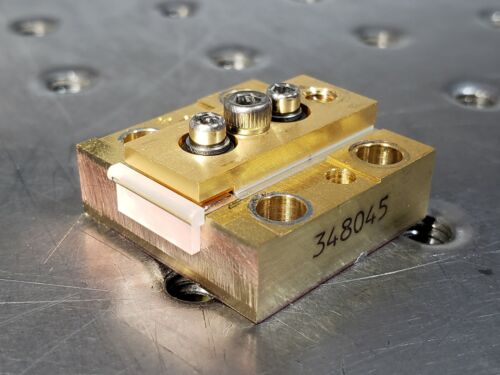

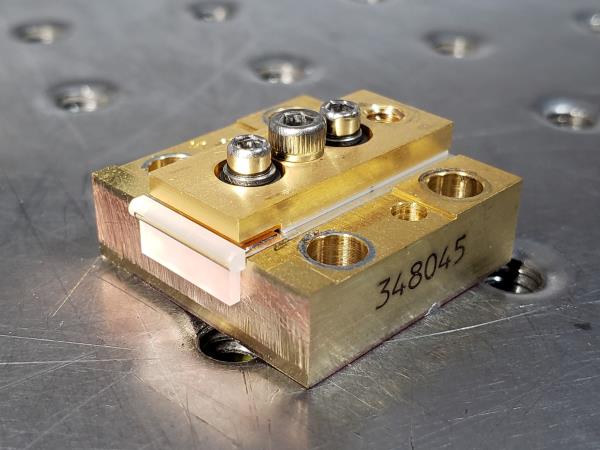

High Power 976nm 40W CS-Mount Laser Diode Bar w/ FAC CCP Tested

conduction cooled (CCP) type which we have cleaned, tested and guarantee

to meet power and wavelength specs.

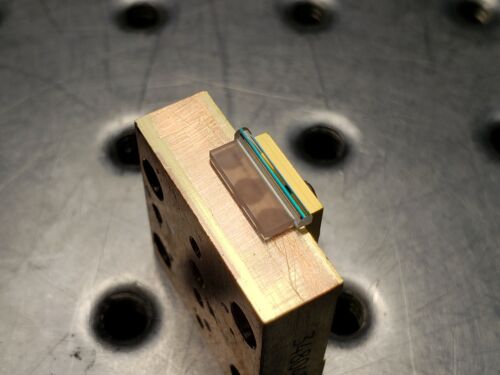

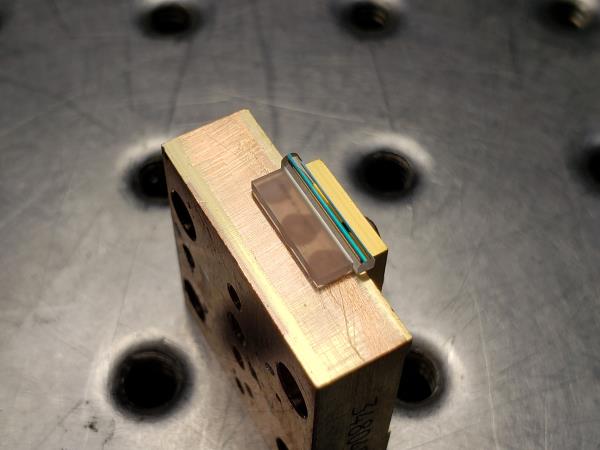

These units have a Fast Axis

Correction (FAC) lens installed which reduces the fast axis divergence

from around 40 degrees to less than 1 degree. The output ‘beam’ is a

narrow stripe about 10mm wide.

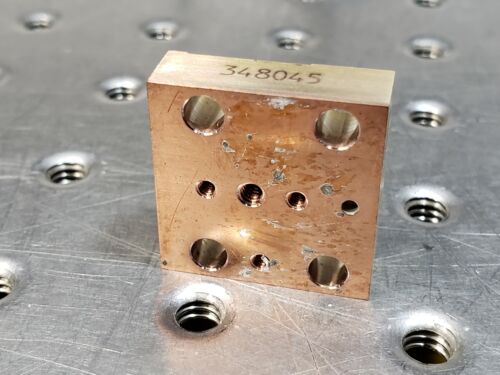

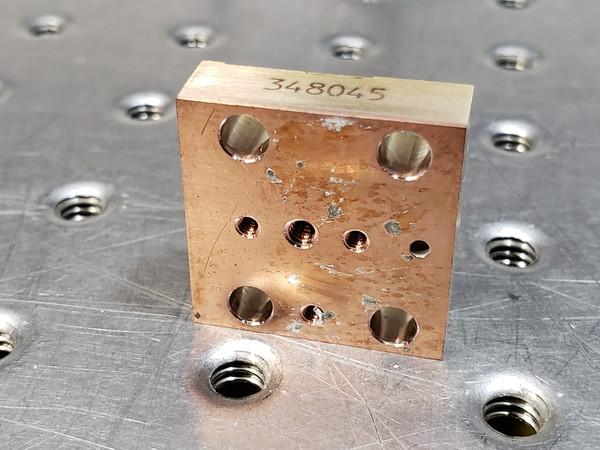

- Type: CS Mount, Conduction Cooled

- Wavelength: 976nm +/- 5nm

- FAC (Fast Axis Correction) Lens: yes

- Power: 40W

- Number of emitters: 19

- Emitter pitch 0.5mm

- Output Width: 10mm

- Slow Axis (H) Divergence: 10 deg typ

- Fast Axis (V) Divergence: 40 deg typ (<1 degree with FAC)

- Maximum current: 48A

- Typical forward voltage: 1.8V

All laser diodes need to be powered with a current regulated laser diode driver. These units need a driver that can source up to 50A with a compliance voltage around 2V. A voltage regulated power supply is not suitable and will damage or destroy the diode. We individually test test all of these with an LDI-830 benchtop laser diode driver and a water cooled test fixture. We’ve also seen good results using Lumina Power LDD-100 and LDD-150 drivers which turn up on eBay from time to time.

These require adequate heat sinking to avoid overheating. For longest lifetime, the diode temperature should be kept below 35C (95F). Water cooling or a large heatsink with a fan will work to prevent overheating. However, a temperature controlled baseplate, typically using 1 or more thermoelectric coolers (TEC) is preferred.

The output from these is a wide stripe of individual emitters. It is not practical to focus the multiple beams to a small spot for marking or engraving. The output is infrared and nearly invisible, but is still quite dangerous. It is critical that you wear laser safety goggles rated as least OD3 while working with these diodes.

Note that these, like all the electrical components we sell, are listed with no returns allowed. They are carefully tested and shipped in anti-static materials so we know they will arrive in good working condition. Laser diodes can be damaged by static electricity, reverse polarity, over-temperature, over-current, none of which is detectable without fully re-testing the unit. We will accept returns for laser diodes which are still in our original, sealed packaging. Once electrical components are opened, we can’t accept returns.

Pictures and description Copyright © 2020 Starlight Photonics, Inc.

Starlight Photonics Policies

PO Box 1134

Alviso, CA 95002

Reviews

There are no reviews yet.