Description

Product Description

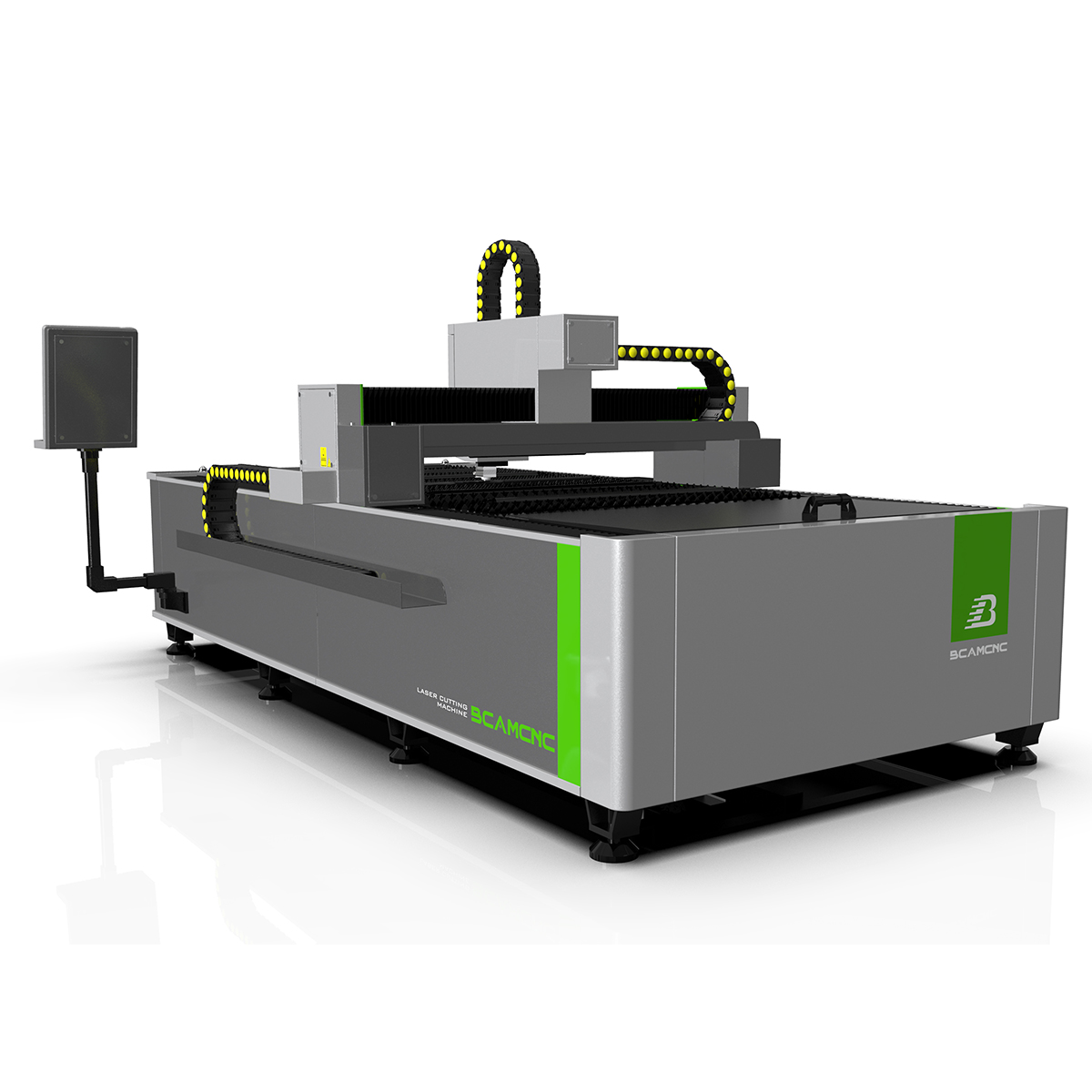

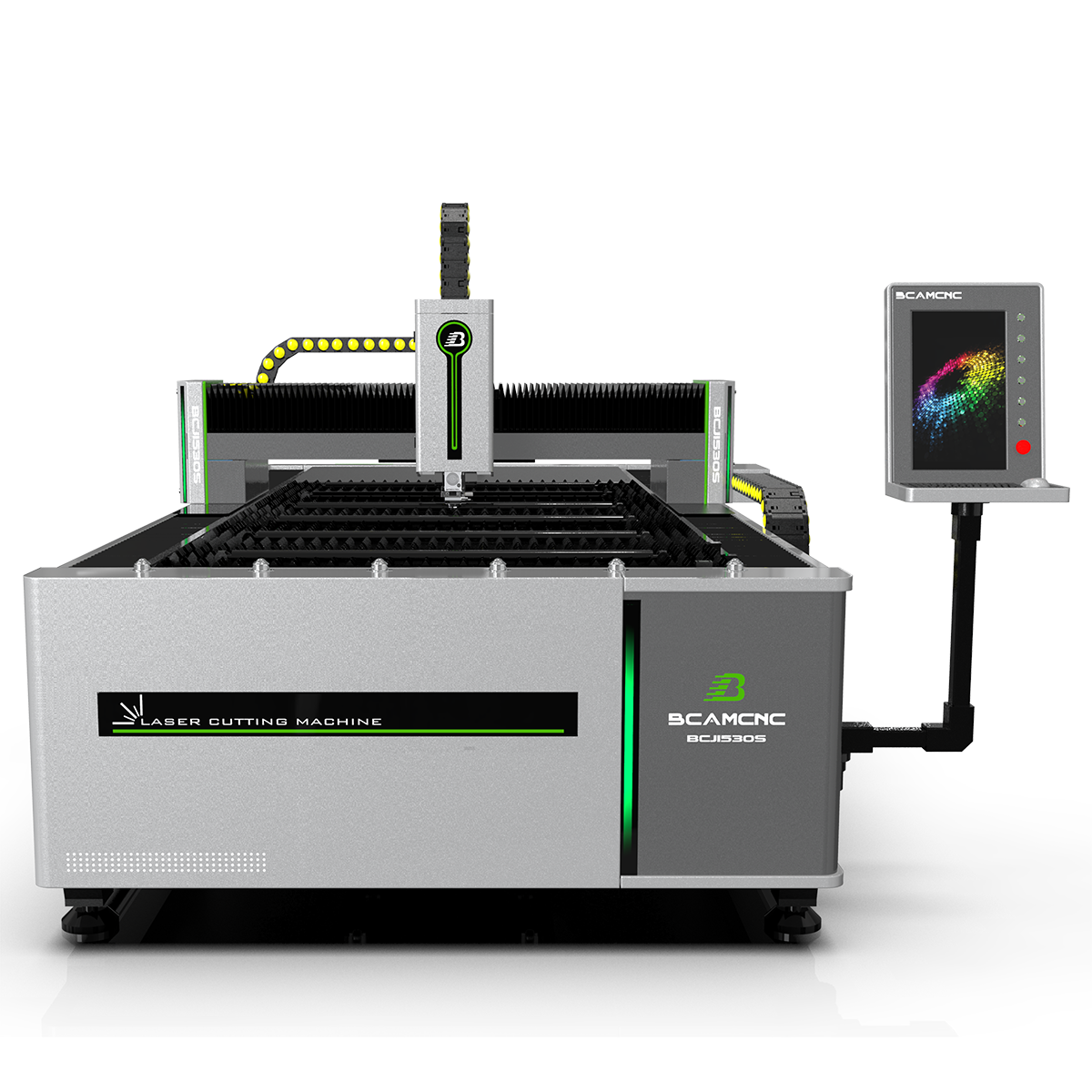

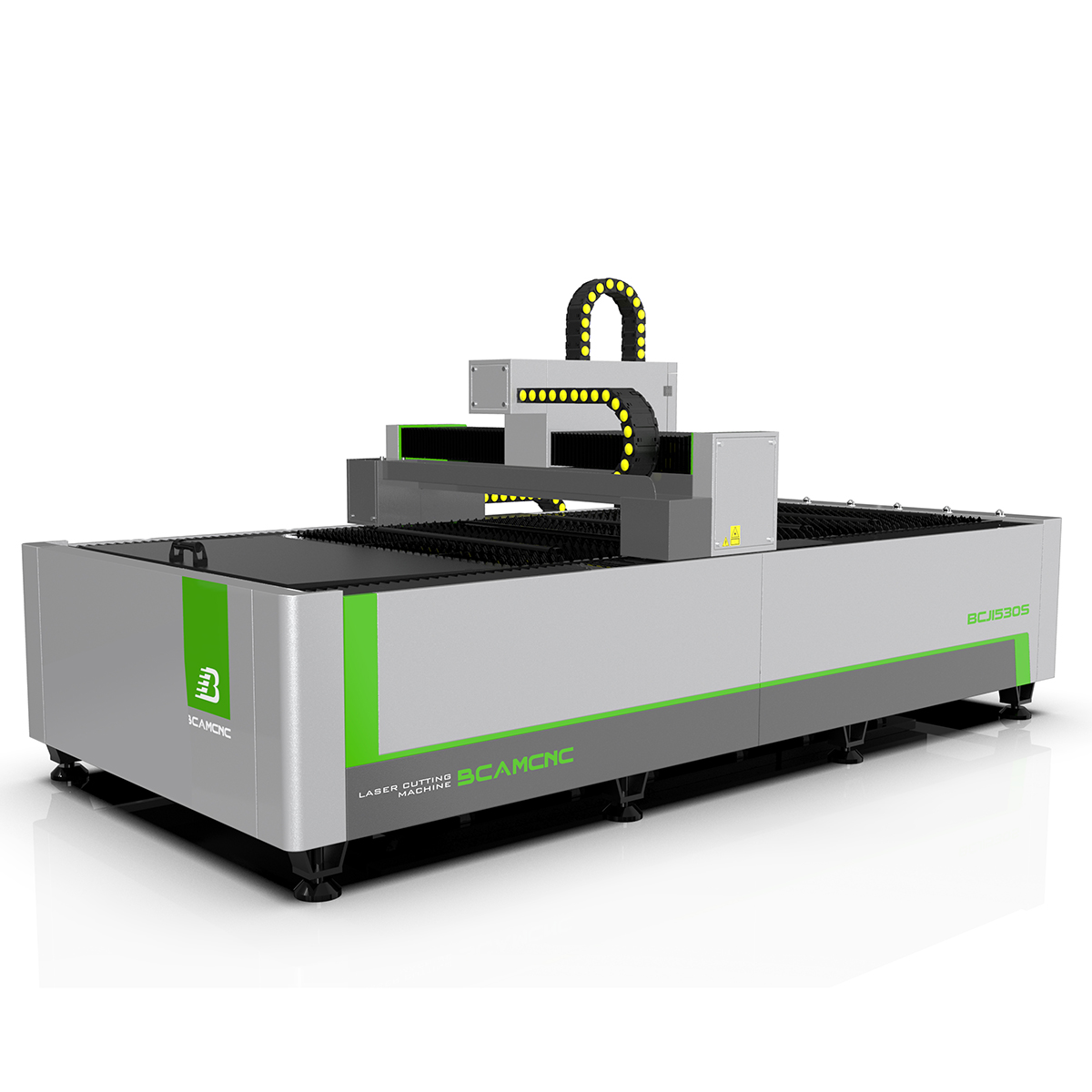

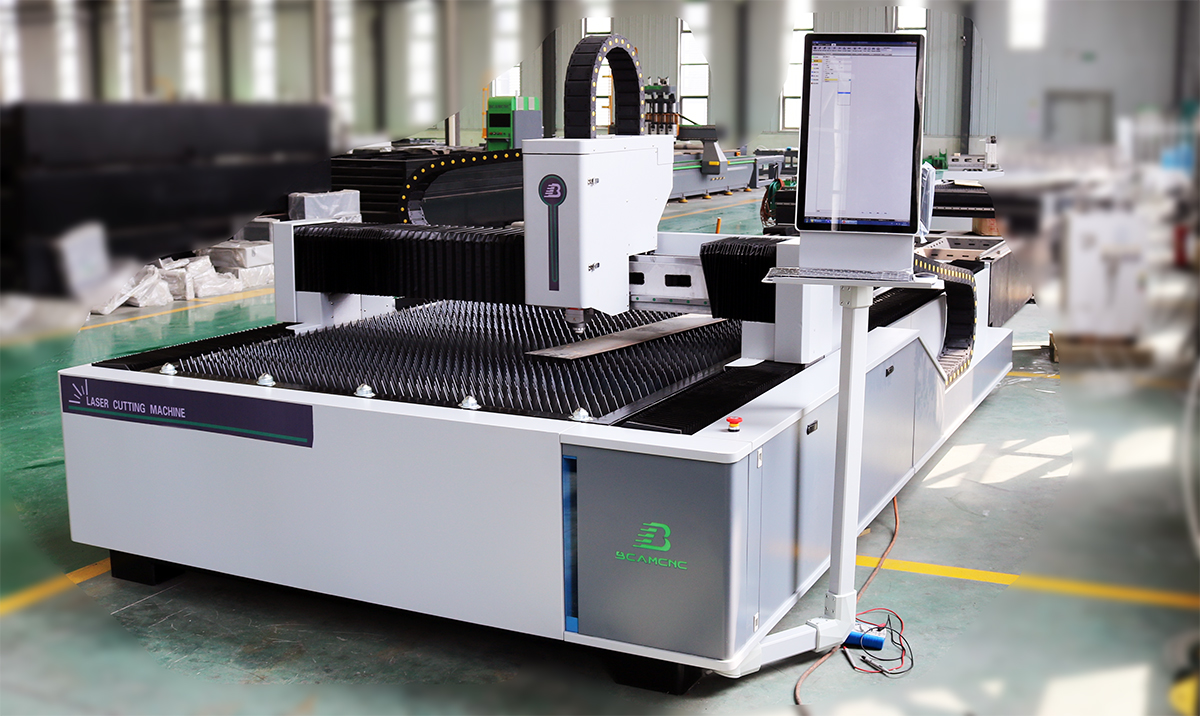

BCJ1530S

High Quality Fiber Laser Cutting Machine for Metal Cut

BCJ1530S is fast speed mild steel cnc fiber laser cutting machine with 3000*1500mm working area, which consist of machine tool,motion parts, electrical equipment control parts, and other assist parts. Via control system to operation three axis motion parts,so it can drive to fiber laser cutting head achieve a stable, accurate, and high speed moving; X and Y axis of aluminium stainless steel sheet cutting machine adopt by imported with original packaging high quality and precision HIWIN linear guide rail, working table adopt by square pipe to welding the overall machine, stress relief annealing treat, the max load-bearing of mesa could get 500 KG, it also has universal ball bearing, machine external set up peripheral clamping device, use full enclosed dust proof device, photoelectric sensor, and other precise positioning parts to ensure accuracy of the transmission.

BCJ1530S is fast speed mild steel cnc fiber laser cutting machine with 3000*1500mm working area, which consist of machine tool,motion parts, electrical equipment control parts, and other assist parts. Via control system to operation three axis motion parts,so it can drive to fiber laser cutting head achieve a stable, accurate, and high speed moving; X and Y axis of aluminium stainless steel sheet cutting machine adopt by imported with original packaging high quality and precision HIWIN linear guide rail, working table adopt by square pipe to welding the overall machine, stress relief annealing treat, the max load-bearing of mesa could get 500 KG, it also has universal ball bearing, machine external set up peripheral clamping device, use full enclosed dust proof device, photoelectric sensor, and other precise positioning parts to ensure accuracy of the transmission.

Details Images

FIBER LEASE HEAD

The laser head body is increased anti-collision function and can be adapted with a variety of fiber laser

LONG LIFE LASER SOURCE

Fiber laser generator with great and stable performance to have lifespan over 100,000 hours Laser source and cost efficient free

maintenance

maintenance

HIGH LIGHT AND RIGIDITY

Aerospace grade aluminum light qualit, high speed.Beam as a whole by the finite element analysis optimization of high rigidity.

INDUSTRY WATER CHILLER

The constant temperature of water chiller can keep the laser power stable,work more stable and fast

HIGH STABILITY BED

To optimize the design of the sectional

welding lathe bed.Lathe bed in the middle of reinforcing bar, improves the

lathe bed stability. The lathe weighs 2.2 T to ensure the accuracy and durability of the equipment

welding lathe bed.Lathe bed in the middle of reinforcing bar, improves the

lathe bed stability. The lathe weighs 2.2 T to ensure the accuracy and durability of the equipment

ORIGINAL GEAR AND GUIDE

World famous imported brand precision linear guides and imported gear racks

Taiwan Hiwin Linear Guide Rail

Taiwan Hiwin Linear Guide Rail

Adopted Taiwan Hiwin linear guide rail, high positioning accuracy, scroll guide, reduce wear to maintain accuracyfor a longer time.

Adopted Taiwan Hiwin linear guide rail, high positioning accuracy, scroll guide, reduce wear to maintain accuracyfor a longer time.

Product Paramenters

|

1

|

Working Area

|

1500*3000mm

|

|

2

|

Laser power

|

1000W German IPG fiber laser generator

|

|

3

|

Wavelength

|

1064nm

|

|

4

|

Cutting speed

|

0-15m/min(depending on material and thickness)

|

|

5

|

Positioning accuracy

|

±0.02mm

|

|

6

|

Repositioning accuracy

|

±0.01mm

|

|

7

|

Eauipment total power

|

25kw

|

|

8

|

Water cooling System

|

Constant temperature water chiller CW6200

|

|

9

|

Power supply

|

380V/3P/50Hz

|

|

10

|

Machine Dimension

|

2100*8000*1600mm

|

|

11

|

Running Environment

|

Temperature: 0℃~45℃

|

SAMPLE

|

1000W cutting process parameters

|

||||||

|

Materials

|

Thickness(mm)

|

speed(m/min)

|

Pressure(bar)

|

|||

|

stainless steel

|

1

|

20-25

|

15

|

|||

|

2

|

6-6.5

|

18

|

||||

|

3

|

2.5-3

|

20

|

||||

|

4

|

0.7-0.8

|

20

|

||||

|

Carbon steel |

2

|

6.5-7

|

0.6

|

|||

|

3

|

2.5-3

|

0.3

|

||||

|

4

|

1.8-2.2

|

0.2

|

||||

|

5

|

1.5-1.8

|

0.15

|

||||

|

6

|

1.1-1.4

|

0.1

|

||||

|

8

|

0.9-1.1

|

0.1

|

||||

|

10

|

0.7-0.9

|

0.1

|

||||

|

12

|

0.6-0.7

|

0.1

|

||||

|

Aluminum Plate |

1

|

10

|

1.2

|

|||

|

2

|

5

|

1.4

|

||||

|

3

|

1.5

|

1.8

|

||||

|

Brass |

1

|

3

|

1.6

|

|||

|

2

|

1.2

|

1.8

|

||||

|

Copper

|

1.5

|

1.8

|

1

|

|||

CERTIFICATE DISPLAY

Our Advantages

BCAM CNC ROUTER MACHINE

1. Ruggedly constructed machine structure. Material is Stress relieved and annealed for deformation free,thus always keep machine

accurate. 2. Machine base is produced by CNC machine, and machine base’s five sides are produced at one same procession to make

sure the machine body geometry tolerance is standard.

3.The unique reality of the 3-axis screw, the machining accuracy is more accurate.

4.The router spindle is very high precision and water-cooled. which keeps the spindle at a constant temperature and maintains

longevity.

5.The router spindle is moved in the three axes by precision ball screw system that are controlled by the machine controller.

6.Bcam group integrates the excellent design, production and logistics resources, specialty engaged in the laser machine,

engraving

machine production and marketing job up to 11 years Now we have mature production workers more than 100 people, 10 sales teams, 2

product research and development teams , 2 after-sales service teams Products exported to Europe,America,Australia ,Africa,Asia

etc, welcomed by consumers and good evaluation Bcam people firmly believe that in the near future.

accurate. 2. Machine base is produced by CNC machine, and machine base’s five sides are produced at one same procession to make

sure the machine body geometry tolerance is standard.

3.The unique reality of the 3-axis screw, the machining accuracy is more accurate.

4.The router spindle is very high precision and water-cooled. which keeps the spindle at a constant temperature and maintains

longevity.

5.The router spindle is moved in the three axes by precision ball screw system that are controlled by the machine controller.

6.Bcam group integrates the excellent design, production and logistics resources, specialty engaged in the laser machine,

engraving

machine production and marketing job up to 11 years Now we have mature production workers more than 100 people, 10 sales teams, 2

product research and development teams , 2 after-sales service teams Products exported to Europe,America,Australia ,Africa,Asia

etc, welcomed by consumers and good evaluation Bcam people firmly believe that in the near future.

Reviews

There are no reviews yet.