Description

Product Description

Attention

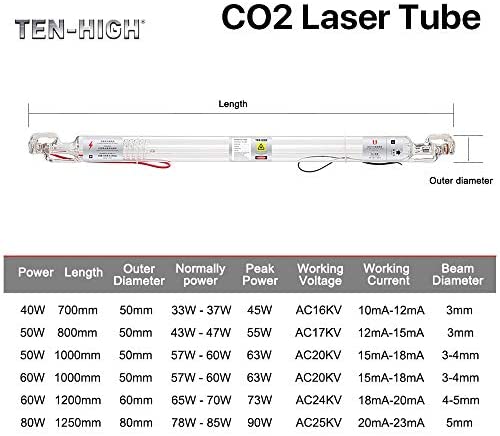

- Before placing order, please confirm the Diameter and Length of the laser tube. (Please make sure your machine has enough installation space, all should be a little bigger than laser tube’s size.)

- Each tube has been tested and we will provide a safe packaging. If there’s any problem after you received the tube, do tell us. We Don’T Want Our Customer To Waste Their Time And Money, and willing to provide the best services.

- Laser tube is consumable, a long-time storage may lead to power attenuation. Thus, we recommend to buy it when you need to use, and after receive the tube, test it first. If there any problem, let us know in time, and we will provide after-sales services for free within 3 months. We Are Always Responsible For Our Products.

- For engraving, it’s recommended to use machine of power below 80W. Because the diameter of laser beam is slender, which is more accurate. For cutting, machine of power above 80W is commonly used. Because the laser beam spot is bigger and more powerful.

- If there doesn’t have the tube that you want or you have some special needs, feel free to let us know, so that we can customize for you.

Product Details

Length 1250mm (±30mm) Diameter 55mm (±2mm) Power 60W Wavelength 10.6μm Laser Beam Diameter 4-5mm Mode TEMOO Package 1 pcs, 4.4KG

Working Current 18mA-20mA (Max 22mA) Maximum output current DC23mA Input Voltage AC90-120V / 200-240V Working Voltage 24KV (Max output power DC28KV) Trigging voltage 28KV Response Time <1ms (from input to the output current reaches the nominal value) Engraving Depth 0-10mm

Frequently Q&A

- Q: Is this tube compatible with my machine?

- A: We suggest to refer the Accessories List of your machine first, to confirm the DIAMETER, LENGTH and POWER of the tube. Size fits, compatible.

- Q: How does the product come packaged?

- A: Tightly embrace the laser tube with high-density sponge. Double foam rubber, Double boxed. We keep improving our packaging, listening patiently to the feedback form our customers. If there any problem caused by transport, we will be responsible for it.

- Q: Storage?

- A: Laser tube is consumable, which means that a long-time storage may lead to power attenuation. Thus, we recommend to buy it when need it. After receive the tube, test it first. If there any problem, let us know in time, we will provide 3 months after-sales services for free.

- Q: Difference between glass head and metal head?

- A: The power is the same and does not affect the use. The glass head has higher adhesion at both ends (especially in cold areas), better connection, less gas leakage, which ensure a longer services life.

- Q: How about the wiring method of the two ends?

- A: Wrap the metal wire on the carbon rod, fix it tightly with solder, then put on the insulating tube, and finally pour 704 glues into the tube.

- Q: How to insulate the high-voltage end?

- A: 1) As mentioned in the previous QA, after putting on the silicone tube, pour 704 glues inside. 2) Wrap a few more turns with electrical tape.

- Q: Power weak? Died too soon?

- A: Please let us know in time, we will send a replacement for free within 3 months.

- Q: Beam does not exit Tube?

- A: It may because of some incorrect operating of the laser machine. Feel free to let us know, to get some support.

- Q: Size of the water hose for inlet and outlet?

- A: Tube of Diameter 7mm x 11mm (0711), or of Diameter 6mm x 8mm (0608). (0711 is better because it’s thicker.)

- Q: What choice TEN-HIGH Laser Tube?

- A: We have more than 7 years of solid experience in laser industry, and are the earliest seller of CO2 Laser Tube. Over the years, we keep improving our product quality, as well as its packaging, according to customer’s feedbacks. Our aim is to create value for our customers and always be responsible for the products we sell. We are your trusted partner for laser accessories.

After coating, the laser power can be increased at least 5%. (Compared to non-coating tube)

Installation Steps

Installation Steps

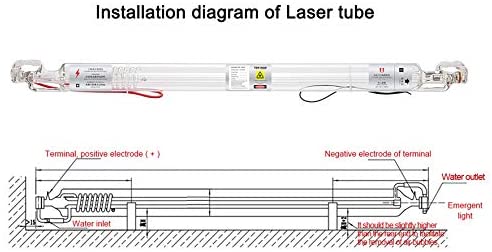

- Determine the Positive and Negative poles of the laser tube. (the end with the spiral inside is the positive end)

- Connect the positive end and negative end with the machine’s wires correspondingly. (Pay more attention to the insulation, especially the high-voltage end, you can wrap with electrical tape a few more turns, or seal with 704 silicon rubber.)

- Please Connect the Cooling Water Pipe. Feed water from the positive pole, the negative pole is out of water. Put the inlet and outlet water pipes into water, keep the water inlet under the laser tube and the interface cannot be leaked. Circulating water cooling, at least 20L. Before use, the water reservoir must be filled with water. (The laser tube has 3 layers in total. The innermost layer pass laser, the outermost layer is filled with CO2, and the middle layer is for the cooling water. There must be no water in the innermost and outermost layers.)

- Adjust the optical path with the laser and test switch on the machine, to make the laser point enter from the middle of the entrance hole of the laser head, and then adjust the vertical optical path. (If the power is weak, try to wipe the lens at first.)

Maintaining Suggestion:

- Confirm whether the water circulation works well every time before use.

- Water temperature should be controlled at 20℃-30℃.

- The laser tube is made by glass, which is fragile. Thus, be careful when installing and using it.

- Avoid the dust accumulation nears to the high voltage electrode, keep it dry and clean, and keep the high voltage end away from the metal as much as possible. Otherwise, it may cause damages to the mainboard.

- The cooling water should be replaced in time:

- Summer: Replace the water every 2 weeks at least (you can put some ice in the water for cooling down);

- Winter: replace the water every 4 weeks at least (do not let the water freeze);

- The higher the machine power is, more often need to replace the water.

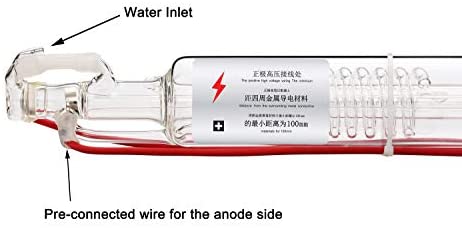

Positive pole:

The positive pole is the high-voltage end, connect with the positive terminal of the machine and the inlet water pipe, to feed cooling water in. (Pay more attention to the insulation, especially the high-voltage end, you can wrap with electrical tape a few more turns, or seal with 704 silicon rubber.)

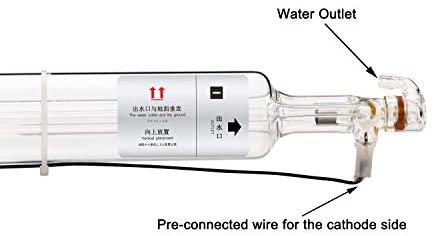

Negative pole:

The negative pole is out of water, connect with the negative terminal of the laser machine. (Make sure that the inlet is lower than the outlet.)

Easy installation:

Wire preconnected: the wires of the two ends, positive pole and negative pole, are connected in advance. Just connect with the wires of your laser machine correspondingly, then make sure the insulation. If any question during installing, feel free to let us know.

ZnSe Focal Lens GaAs Focal Lens Mo Reflective Lens K9 Gold-Plated Glass Reflective Lens Laser Power Upgraded Laser Tube Diameter 12/15/18/19.05/20/25/25.4mm 18/19.05/20/25/25.4/28mm 20/25/30mm 20/25mm None None Focal Length 25.4/38.1/50.8/63.5/76.2/101.6/127/190.5 mm 50.8/63.5/76.2/101.6/127mm None None None None Wavelength 10.6um 10.6um 10.6um 10.6um 10.6um 10.6μm Power 30W-400W 100W-600W 40W-100W 40W-50W 40/50/60/80/100/150W Please refer to Product Details Coating ✓ ✓ X ✓ ✓ ✓

ZnSe Focal Lens GaAs Focal Lens Mo Reflective Lens K9 Gold-Plated Glass Reflective Lens Laser Power Upgraded Laser Tube Diameter 12/15/18/19.05/20/25/25.4mm 18/19.05/20/25/25.4/28mm 20/25/30mm 20/25mm None None Focal Length 25.4/38.1/50.8/63.5/76.2/101.6/127/190.5 mm 50.8/63.5/76.2/101.6/127mm None None None None Wavelength 10.6um 10.6um 10.6um 10.6um 10.6um 10.6μm Power 30W-400W 100W-600W 40W-100W 40W-50W 40/50/60/80/100/150W Please refer to Product Details Coating ✓ ✓ X ✓ ✓ ✓

Robert R. –

I bought this tube (60w) to replace the tube in my Chinese laser. Tube fit perfectly into my machine. Connections for cables were solid and shielded well with silicone. I was able to replace my tube in less than 30 mins. Packaging was solid and tube was secured very well in multiple boxes.