Description

- Motor Type: DC Motor

- Certification: CE

- Origin: Mainland China

- Power Supply: DC

- Model Number: laser diode driver

- Voltage: DC 2.7 ~ 9V

- suitable for: 520nm 650nm 405nm 450nm laser diode

- Current: 10mA ~ 300mA

- Operating temperature: 10 ~ 75

532nm 650nm 635nm 780nm 405nm 450nm Red Blue Purple Green Laser Diode Driver Circuit Board

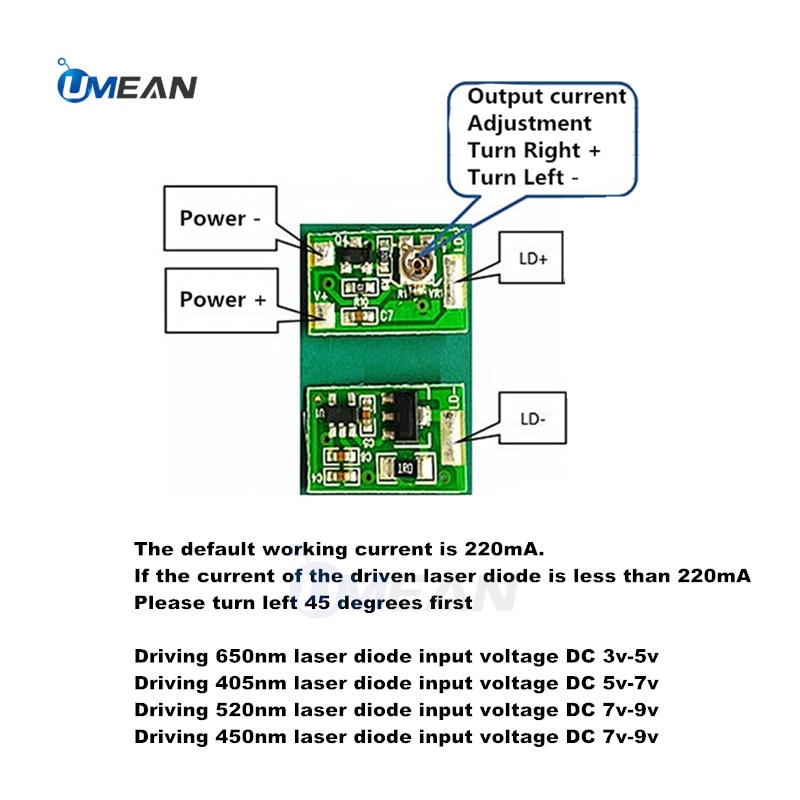

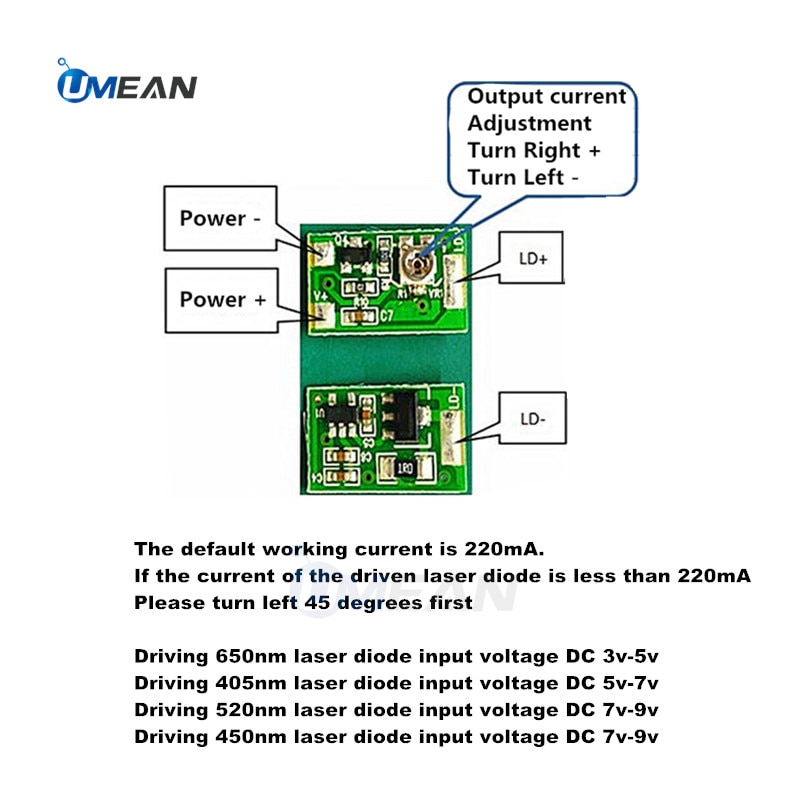

Circuit parameters:

Input voltage: DC 2.7 ~ 9V

Input current: 10mA ~ 300mA

Output current: constant current setting (can be set according to actual needs: 10ma-300ma)

Laser power: adjustable

Operating temperature: – 10 ~ 75 ° C

Working efficiency: 99%

Certification: it can pass CCC and CE certification

Overcurrent protection: Yes

Short circuit protection: Yes

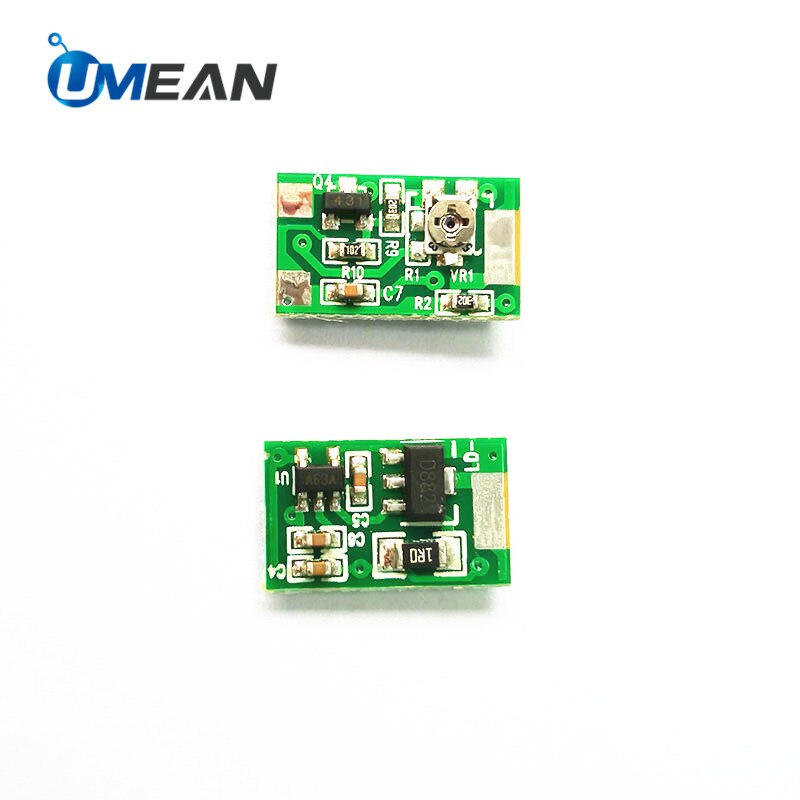

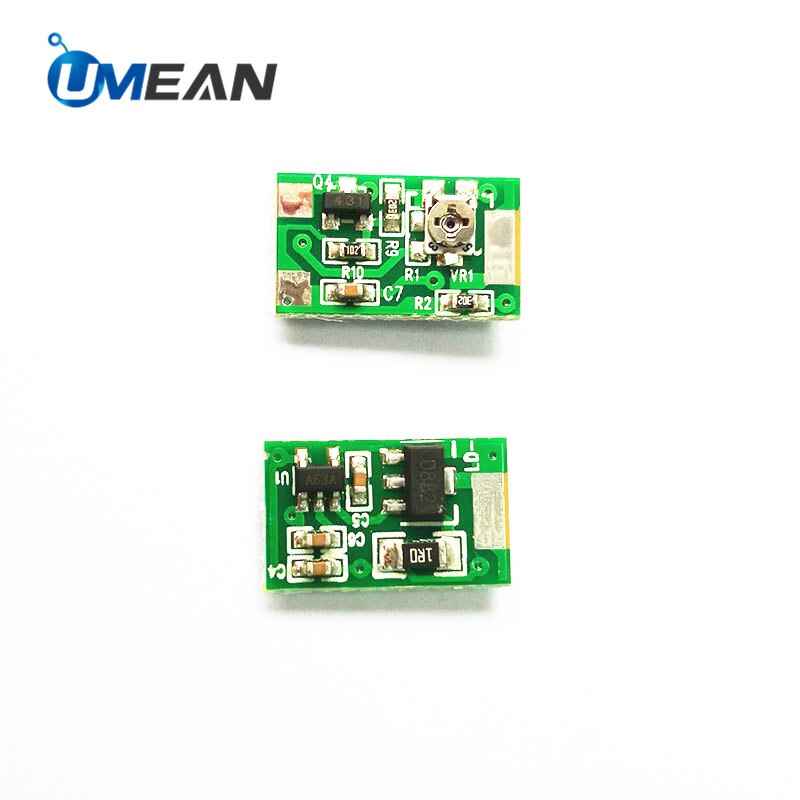

Dimension: L * w * H = 15 * 9 * 4.5mm

Quantity: 1 piece

PACKAGE:

1 piece * Laser Diode Driver Circuit Board (No including the laser)

NOTE:

Need to take care about the laser diode output voltage , to avoid damage of the laser diode .

This item is sensitive for static,please keep in mind that DO NOT touch this item unless you Wear anti-static wrist strap when working with the laser.

Notice:

1 . This laser diode may do harm to human eyes, when the laser tube is working, pay no direct attention to it.

2, The laser tube requires a suitable power supply, transient reverse current can`t exceed 32mA, reverse voltage can`t exceed 4.7V, otherwise it will damage the laser tube.

Test the laser tube: insert or pull out the laser tube after the power off. Do not plug or unplug the laser tube when the power on, otherwise the laser tube will be damaged, invalid.

3, The laser tube should be kept or working in a dry environment to prevent condensation, condensation may damage the laser tube.

4, At high temperatures, it will increase the threshold current, lower the efficiency and accelerate the aging of the laser tube.

5,When the output power higher than the specified parameters, it will accelerate the aging of the laser tube.

6, The laser tube need to be used in fully heat or cooling conditions

7, Laser diodes are ESD sensitive device, anti-static measures should be prepared. Before pick up the case, make sure you get a good grounding condition, otherwise the laser tube will be easily to breakdown by the static electricity, resulting in the laser tube failure. Wear anti-static wrist strap when working with the laser.