Description

- Brand Name: ACCTEK

- Origin: CN(Origin)

- Certification: CE

- Condition: New

- Model Number: AKJ1530F

- CNC or Not: CNC

- Is Smart Device: No

- MOQ: 1 set

- Transmission: YYC Gear Rack transmission

- Drive mode: Delta servo/Yaskawa servo 1800W

- laser power: 1kw/1.5kw/2kw/3kw/4kw/6kw/8kw

- control system: Au3tech control system

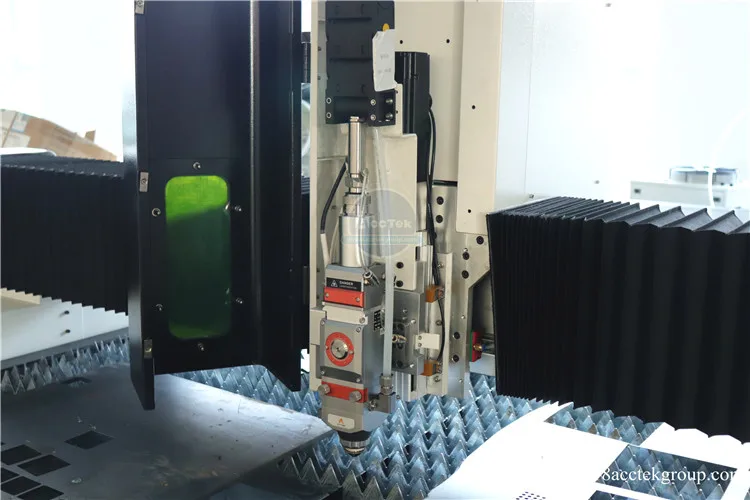

- Laser head: Au3tech laser cutting head

- Warranty: 3 years for machine

- laser generator brand: Raycus/ IPG/ MAX/ Reci

- Gear and rack: Taiwan APEX gear and rack

- Reducer: French MOTOVARIO reducer

- Rails: Taiwan Hiwin guide rails

- Table Size: 1500*3000mm

3015 Table Size Metal 1000W Fiber Laser Cutting Machine For 6mm Carbon Steel

Why Laser Beams Are Better Than CO2 Beams

The biggest advantages of using beams with limited wavelengths are:

#Cut materials considered ‘problematic’ or tough including non-ferrous metals such as brass, copper, and aluminum.

#Improve focus

#Increase rate of cutting

#Lower heat dissipation

#Smoother cut surfaces

Parameters of 1000W Fiber Laser Cutting Machine

|

1 |

Model |

AKJ1530F |

|

2 |

Laser power |

1000W /1500W/2000W /3000W /4000W/8000W/12000W(Optional) |

|

3 |

Dimensions |

4600*2450*1700mm |

|

4 |

Working area |

3000mm x 1500mm |

|

5 |

Repeat positioning accuracy |

±0.02mm |

|

6 |

Maximum speed |

120m/min |

|

7 |

Max. acceleration |

1.0G |

|

8 |

Max Cutting Speed |

80m/min |

|

9 |

Motor &driver |

Japanese YASKAWA brand servo / Delta servo motor |

|

10 |

Laser head |

Au3tech laser head /Raytools laser cutting head |

|

11 |

voltage |

380V 50Hz/60Hz/60A |

Features of 1000W Fiber Laser Cutting Machine

1. Application of gantry structure and integrated cast cross-girder to achieve higher rigidity, stability, shock resistance.

2. High-performance laser source and stable operating Cypcut system which makes the best cutting effect.

3. The machine owns a perfect cooling system, lubrication system, and dust removal system, to ensure that it can operate stably, efficiently, and durably.

4. The machine is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

5. The specialized CAD / CAM automatic programming software and automatic nesting software aim to maximally save raw materials.

Detail photos of 1000W Fiber Laser Cutting Machine

Detail imagines:

Raycus laser source.

Fiber laser is compact in structure, stable in performance and widely used, Fiber laser has high photoelectric conversionefficiency,

good beam quality and low maintenance cost,(Germany IPG and Reci and MAX Laser source is optional)

Water chiller:

Dual temperature fiber chiller is used to cool both the fiber laser and the QBH connector.

Users can manually set water temperature control working mode according to actual needs.

Application materials of 1000W Fiber Laser Cutting Machine

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet(tube), Mild Steel Plate(tube),

Carbon Steel Sheet(tube), Alloy Steel Plate, Spring Steel Sheet(tube), Iron Plate(tube), Galvanized Iron(tube),

Galvanized Sheet, Aluminum Plate(tube), Copper Sheet(tube), Brass Sheet, Bronze Plate, Gold Plate, Silver Plate,

Titanium Plate, Metal Sheet, Metal Plate Tubes and Pipes, etc

Application industry:

This Fiber Laser Cutting Machine is applied in sheet metal processing, aviation, spaceflight, electronics,

electrical appliances, subway parts, automobile, machinery, precision components, ships, metallurgical equipment,

elevator, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Our service:

Pre-sale

1)Professional sales team and engineer team provide professional technical Support

2)24 hours of online service each day,you can contact us by email, Whatsapp, Skype, Wechat, Phone number, and so on.

3)Test video and Sample support

4)OEM support

5)Certificate support: CE

In-sale Service

1)In the processing of production, our professional technical engineers inspect the processing to ensure the quality of products

After our machine finish, our engineer will make 24 hours test constantly and ensure the machine reach the best performance.

2)Shooting working video and machine pictures for customers' confirmation.

Shoot delivery video, parts pictures in every detail, and save on file so that our after-sale team can help customers solve questions faster.

After-sale

1. 3 years quality guaranty (1.5 years for laser generator), the machine with main parts(excluding the consumables) shall be

changed free of charge when if there is any problem during the warranty period.

1. Lifetime maintenance free of charge.

3. Free training course at our plant.

4. We will provide the consumable parts at an agency price when you need replacement.

5.24hours of online service each day, free technical support.

6. Machine has been adjusted before delivery, operation disk and manual was included. If there is also any questions, pleasekindly tell me.

CE certificate:

About AccTek Company:

Our main products are AccTek CNC Routers and Laser engraving and cutting machines. Stock or custom configurations are our specialty.

Components for our machines are sourced from world class suppliers and innovators in machine control.

These machines are used in many industries, crafts and arts businesses around the world. These include woodwork, metal and stone work,

aluminum fabrication, boat building, shop fitting, mold making, to name a few.

Our dedicated and highly skilled after sales service department, sales team, and thorough quality assurance procedures mean that you can buy with confidence.

We welcome customers and potential business associates from around the world. We can work together cooperatively for mutual benefit.

“Our business is to improve your business”

Contact us:

Name : Nina Li

Mob&Whatsapp: +86-18615658712

Skype: acctek18

Wechat: 18615658712

E-mail: export18 (at) acctekgroup.com

Reviews

There are no reviews yet.