Description

- Origin: CN(Origin)

- Item Type: BALL

Characters;

1.All gold tin welding, higher stability and reliability.

2.Full sealed nitrogen filling treatment, strong environmental adaptability;

3.Macro channel cooling structure, water cooling is simple;

4.100W / bar, high energy density, easy to shape;

|

Model

|

DVS-L-1006/1008/1010BAI

|

DVS-L-1012BAI

|

DVS-L-1015-1020BAI

|

|

Peak Power

|

600/800/1000W

|

1200W

|

1500-2000W

|

|

Central

Wavelength

|

808±10nm

|

808±10nm

|

808±10nm

|

|

Fast axis

divergence

|

≦31°

|

≦31°

|

≦31°

|

|

Slow axis

divergence

|

≦2°

|

≦2°

|

≦2°

|

|

Bar Space

|

3.54mm

|

2.94mm

|

2.34-2.14mm

|

|

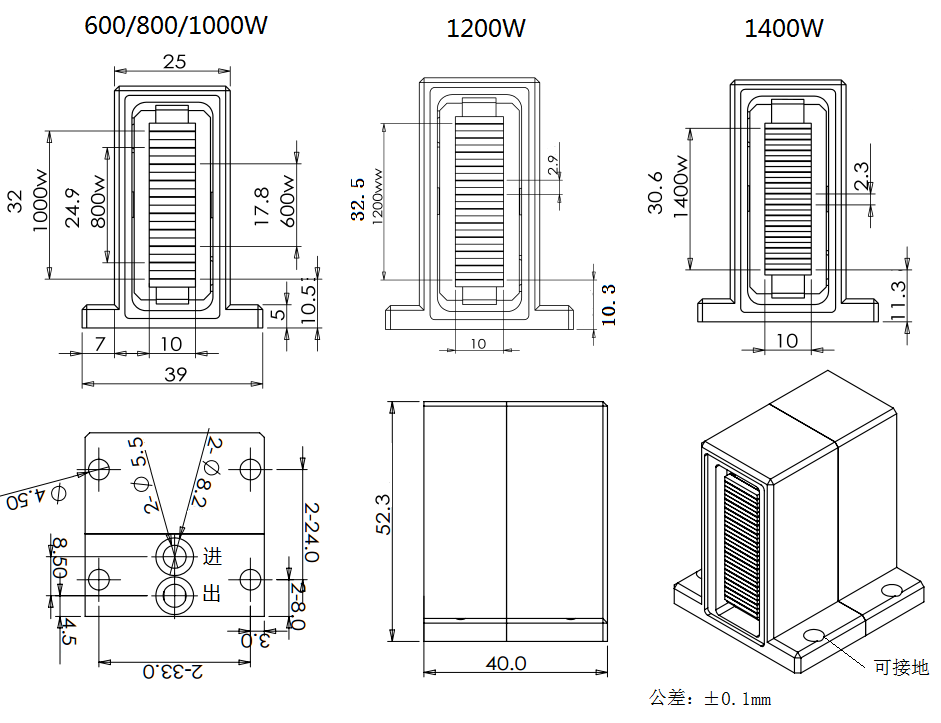

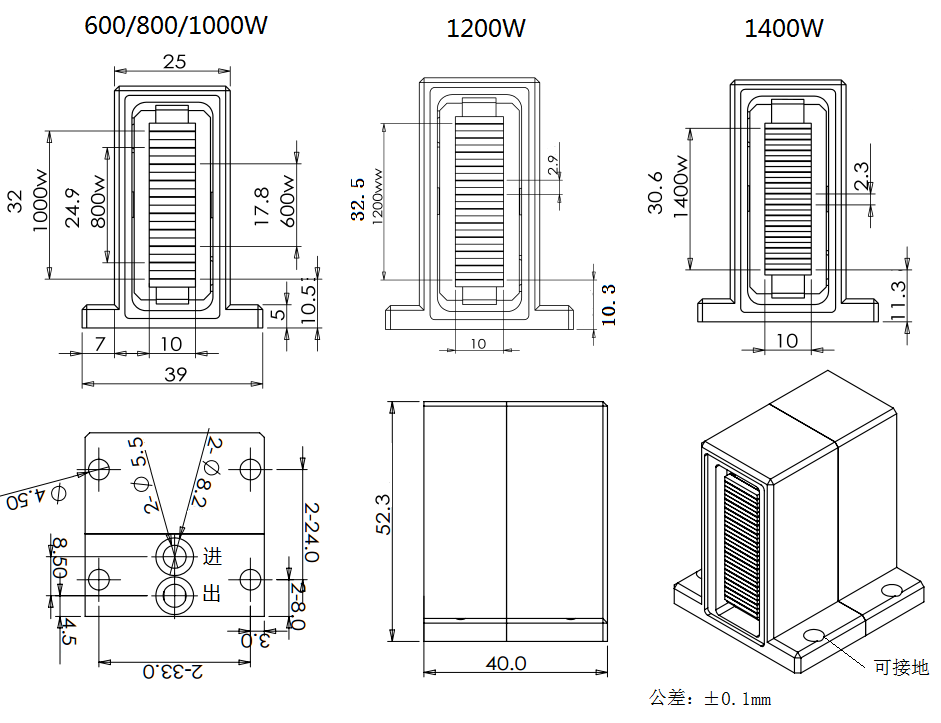

Spot Size

|

10×17.8/24.9/32mm

|

10×32.5mm

|

10×30.6mm

|

|

Drift

coefficient

|

0.28nm/℃

|

0.28nm/℃

|

0.28nm/℃

|

|

Threshold

current

|

18A

|

18A

|

18A

|

|

Working Current

|

≦90A

|

≦90A

|

≦90A

|

|

Max

Current

|

100A

|

100A

|

100A

|

|

Max Working

Voltage

|

2.0V/Bar

|

2.0V/Bar

|

2.0V/Bar

|

|

Repetition

rate

|

1~10Hz

|

1~10Hz

|

1~10Hz

|

|

Maximum

duty cycle

|

20%

|

15%

|

10%

|

|

Maximum

pulse width

|

200ms

|

150ms

|

100ms

|

|

Working

environment temperature

|

15~35℃

|

15~35℃

|

15~35℃

|

|

Optimum

water temperature

|

20-25℃

|

20-25℃

|

20-25℃

|

|

Storage

temperature

|

-10-60℃

|

-10-60℃

|

-10-60℃

|

|

discharge

|

>3.0L/min

|

>3.0L/min

|

>3.0L/min

|

|

Hydraulic

pressure

|

0.4-0.6MPa

|

0.4-0.6MPa

|

0.4-0.6MPa

|

|

Water

quality requirements

|

Deionized water of grade III or above, conductivity ≤ 10us / cm, resistivity ≥ 1 m Ω·

cm, particulate matter ≤ 6 μ M

|

Note: Semiconductor laser chip withstands a maximum current of 100A. This current will directly shorten the service life of the laser. It is only used in the rapid aging experiment of the laser. It is not recommended for the customer to use. As a result, the service life of the laser will be shortened or burned out, which is not within the scope of quality assurance.

1, “LD+” for the laser module positive connection terminal;

2, “LD-” is the negative terminal of the laser module;

3, “V+” for switching power supply positive input;

4, “V-” for switching power supply negative input;

5, “GND 12V” for the 12V power supply input;

6, “G A D” for the external control signal input. G control signal of common ground; A control analog signal input end of the cathode (corresponding to the 0-4V output current of 0-50A, external control analog signal drive current should be greater than 1mA; D) for external control under the condition of laser switch control input interface, the input TTL signal, high effective.

Notes for use of lasers:

1. The ideal temperature of cooling water is less than 25 ~C. It is suggested that the laser temperature should be controlled at room temperature (+5 ~C) to avoid condensation. The lower water temperature can prolong the service life of the laser and reduce the wavelength drift.

2. The actual water flow of each heat sink flowing through the laser is more than 3.5L / min.

3. Please use it in a dry and clean environment. No dirty water stains are found in the product windows.

4. Reasonable size O-rings must be selected to connect the inlet and outlet holes of the products. Too small size can easily increase the invalid water resistance of the waterway, too large size can easily be extruded and twisted.

5. In order to ensure the long-term use of this product, please use deionized water for circulating cooling, periodically replace deionized water and filter system filter element, it is recommended to replace deionized water once every two weeks.

6. the outer conductor wire diameter of the laser is larger than 6m.

7. if the customer needs the ground wire, it can connect itself to the four screws on the module base.

8. If customers use constant current supply, they must pay attention to avoid the invalid resistance in the welding circuit, so as to reduce load changes and protect the laser; in addition, the instantaneous pulse power of the current output signal should not be higher than 100A, otherwise the laser will be burned.

9. Attention should be paid to the electrostatic protection of the laser when the laser module is unpacked and installed. The welding tool must be grounded.

10. Customers need to open and close the pump or intake valve more than three times each time they start the machine, so that the air in the water passage cavity can be discharged smoothly.

11. The low current 30A is used for trial operation before the laser is energized, and then the standard current is used to effectively protect the characteristics of the chip.