Description

- Brand Name: TwoWin

- Origin: CN(Origin)

- Certification: CE

- Condition: New

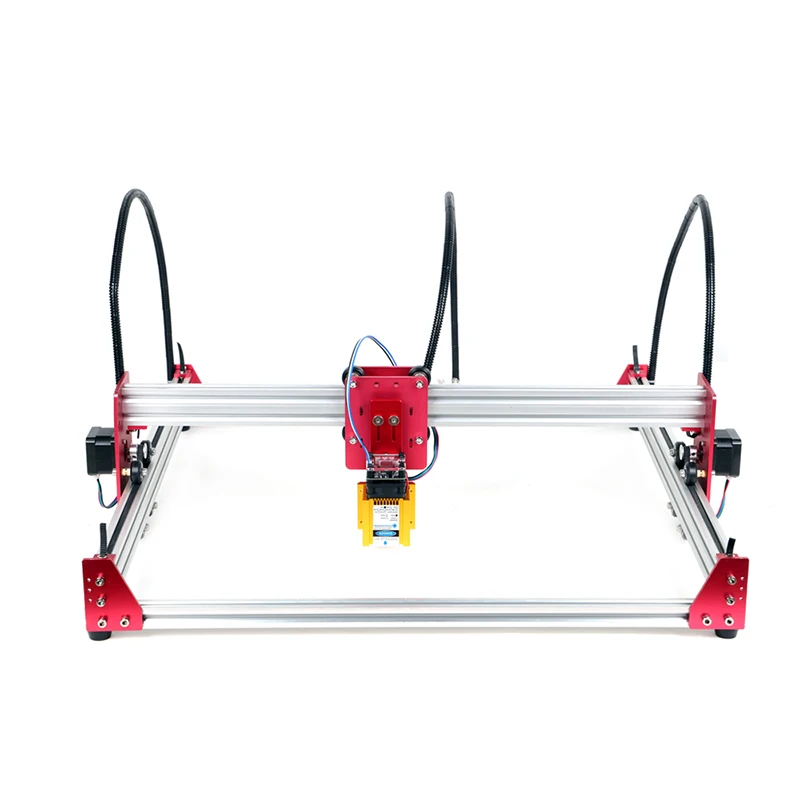

- Model Number: CNC 4545

- CNC or Not: CNC

- Is Smart Device: No

- engraving area: 45*45cm

- Function: wood routers

- Usage: CNC DIY Milling/mini cnc machine

- Laser: 500mw/2500mw/5500mw/7w/15w

Feature:

Model: 4550

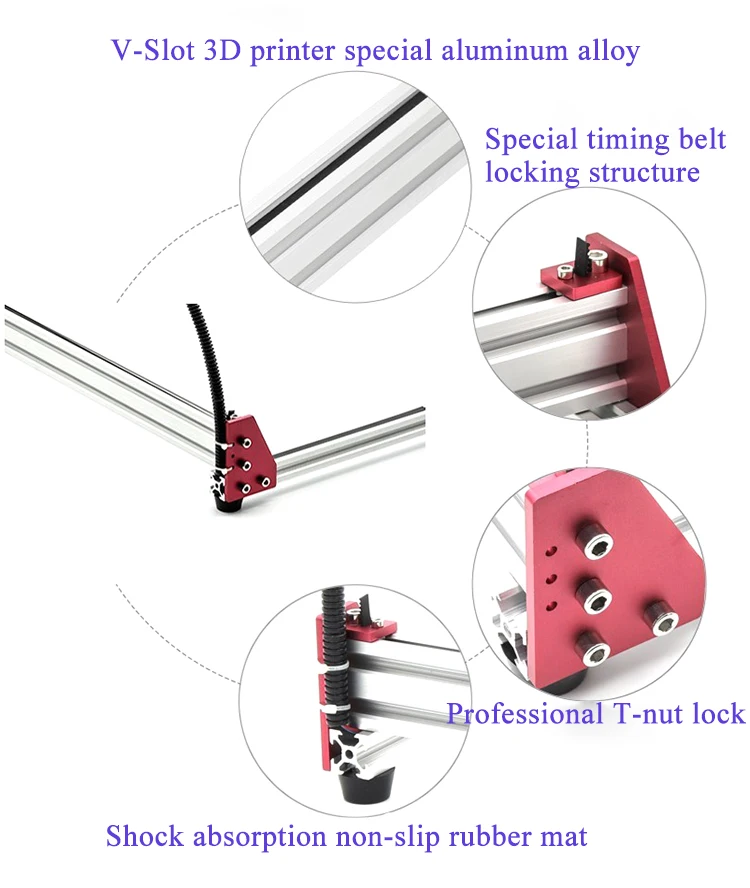

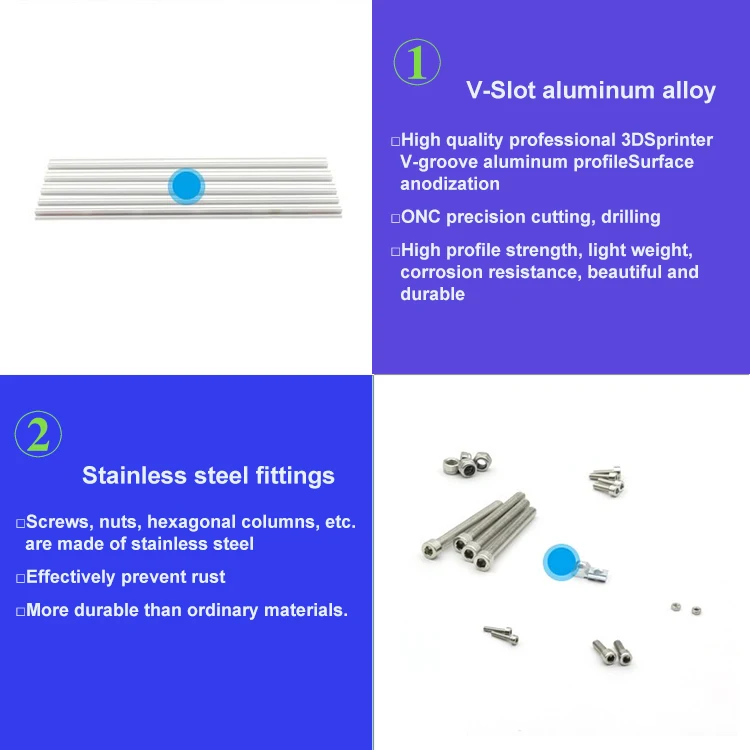

Material: Aluminum Profile

Working area: 45cm *45cm

Packaging Size: 68x40x12cm I 26.77×15.75×4.72inch (L*W*H)

Package Weight: 6.50kg

Can Engrave: Determined by laser module power

Laser Power: 5.5W

laser Wavelength: 450nM

Beam Shape: 0.1mm Point

Focal Length: Less than 3cm

Material: Aircraft Aluminum,Copper

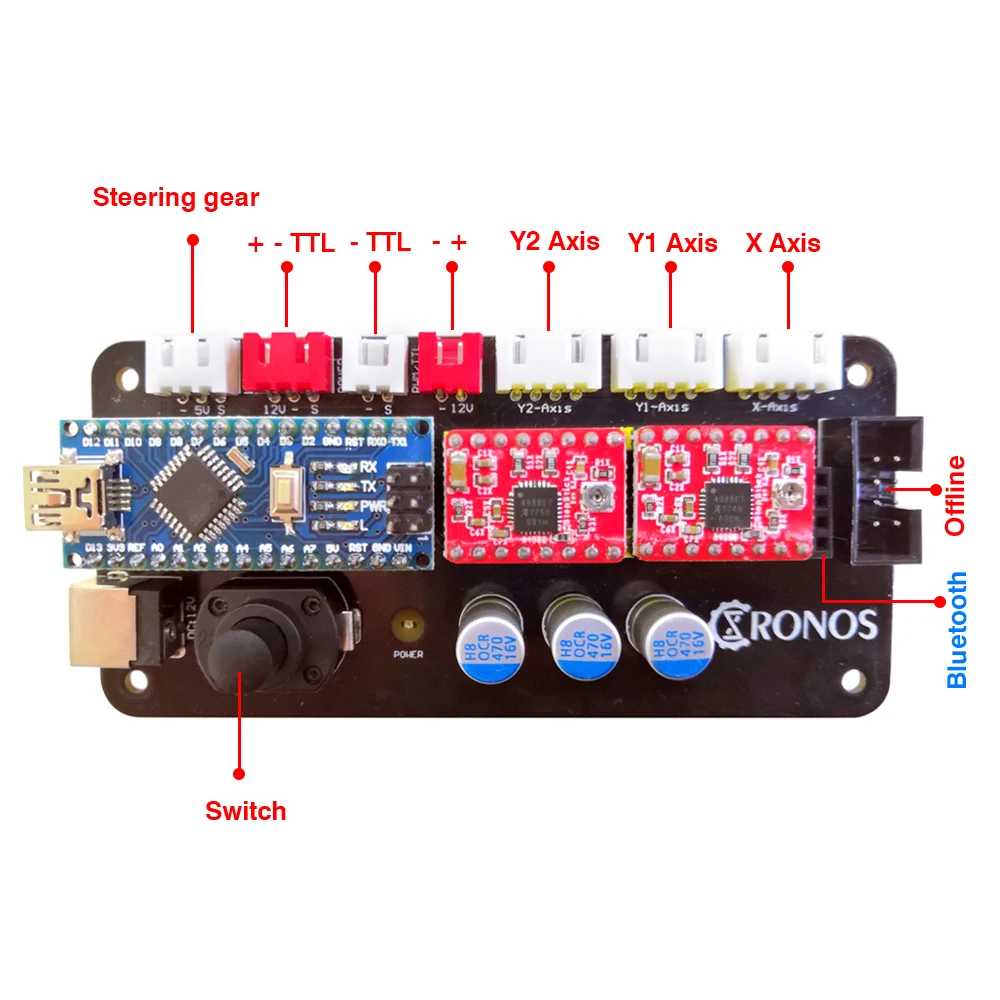

Power Support Input Voltage: DC 12V

PWM Support Input Voltage: DC 5V

Power Supply Interface : XH2.54*3P

Driving mode: External ACC Constant Current Drive

Can Engrave:MDF/Balsa/Paper/Wood/Fabric/Plastic/Leather/

Plywood/Stainless steel

Can Not Engrave:Metal/Glass/PCB/Reflective Material/

Transparent MaterialStone

Laser Power : Pulse 15W average 8W

laser Wavelength: 450nM

Beam Shape: 0.1mm Point

Focal Length: Fixed focal length

Material: Aircraft Aluminum,Copper

Power Support Input Voltage: DC 12V

PWM Support Input Voltage: DC 5V

Power Supply Interface : XH2.54*3P

Driving mode: External ACC Constant Current Drive

Can Engrave:MDF/Paper/Wood/Fabric/Plastic/Leather/

Plywood/Foam Paper/Anodized Aluminum/Ceramics/

Stone/Stainless steel

Can Not Engrave : Metal/Glass/PCB/Reflective Material/Transparent Material

FAQ:

1. How to assemble the kit?

The entire assembly and operation manual is on the installation CD

2. What software can support this machine? And what image format? Engrave Mode?

Supported Software: EleksCAM,T2-Laser, GrblController, LiteFire, Laser GRBL, etc.

Supported Image Format: jpg, bmp, svg, G-code

Supported Engrave Mode: Photo, Word, Scan, Outline, Pixel Laser

Engraving

3. What system can support?

PC Windows XP/7/8/10 , Laptop is ok,too.

4. My laser doesn't work, what should I do?

If the machine does not work, it might because:

① The wire connection is wrong.Please check the connection like the picture shown.

② Your computer could not support the software.Please use Win XP 7/8/10 to check it.

③ Software problem.Please check whether wires are inserted rightly. And then check your data setting.

④ The kit misses some accessories.Please compare with the instruction and tell us, we will solve it once you send us the email.

⑤ Laser module/ driver board/power supply is broken.Please check which part is the main problem,and then send us a video to prove it.

Or you can send us a video about your software setting,working laser and driver board. We will analyze it and give you a solution.

5: My software shows: Not data, what should I do?

There might be two reasons.

① You did not open Administrator privileges to run the software. Please try this.

② Your computer architecture is incomplete:check whether VC ++ and. Net and directX are installed, and have to turn off the virus.

6. Can I regulate the laser power or the laser power is adjustable?

Our new Mana SE controller board can adjust the power. Please download our software to do it.

7. Can I upgrade stronger power laser module by myself? Can I extent rail frame?

Yes,you can.DC12V laser module can be installled on this machine. The red is positive.You can also extent the frame by yourself,

but we do not provide rails. Please note that.

8. When I click arrows to control the motors, it works. But when I begin to make it work with software,

it does not move. What should I do?

The software could move by hand but could not move when focus.The probelm is the area and language inside the system control panel.

Please set the format to English and United States.Then it will be ok. Detail is shown in the wiki link above.

9. My laser module is always on and could not turn off.What should I do?

Please try to connect the Signal(S) and GND(-).

If the laser module turn off, that means the laser module is ok, the problem might be the ManaSE board or software setting.

If the laser module is still on, that means the laser module might be damaged.

10. If my laser is broken and I might find the reason(Or I could not find) . What should I do?

① Find the reason: Take a video to prove the part is broken and then send it to us. we will give you a solution according to your video.

② Could not find the reason : Check the Question 4 first. If the problem could not be solved, please feel free to contact our customer

The video or photos should contain software setting, broken part details and the power-on machine.We will solve it asap.

Reviews

There are no reviews yet.