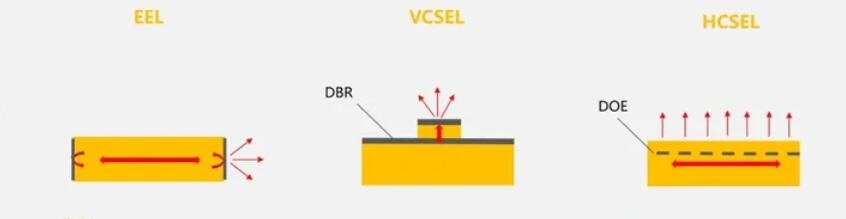

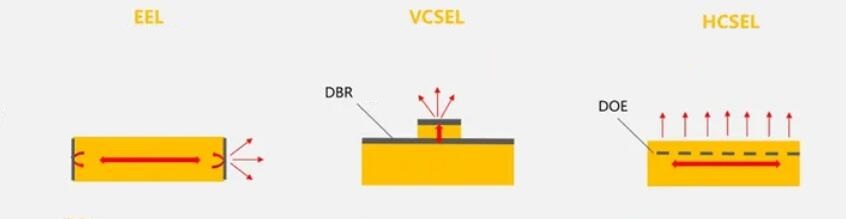

Comparison between HCSEL, VCSEL and EEL

Different from LED light sources, HCSEL laser are horizontal resonance and vertical light-emitting surface of the cavity. It has the advantages of VCSEL in overall tape-out and easy packaging at the wafer level. HCSEL laser has the long cavity length and high power of EEL.

Compared with VCSEL:

1 . HSCEL has better beam quality, better polarization and higher signal-to-noise ratio than VCSEL.

- Narrow spectral linewidth: Narrow spectral linewidth and stable wavelength facilitate effective noise filtering in 3D sensing and LiDAR applications.

- Excellent beam quality: Excellent beam quality reduces the difficulty of optical shaping.

- Excellent polarization degree: Excellent polarization degree is beneficial to sensing detection and optical beam combining.

Comparison with EEL:

- HSCEL laser has higher power, larger output diameter, and simpler manufacturing process than EEL.

- High single-tube power: Ultra-high single-tube power reduces the number of chips used and reduces costs.

- Large output caliber: Large output caliber gives ultra-high chip reliability.

- Simple manufacturing process: Simple chip manufacturing process theoretically ensures that the cost is lower than EEL.