Description

- Brand Name: Nakupenda

- Origin: CN(Origin)

- Certification: CE

- Condition: New

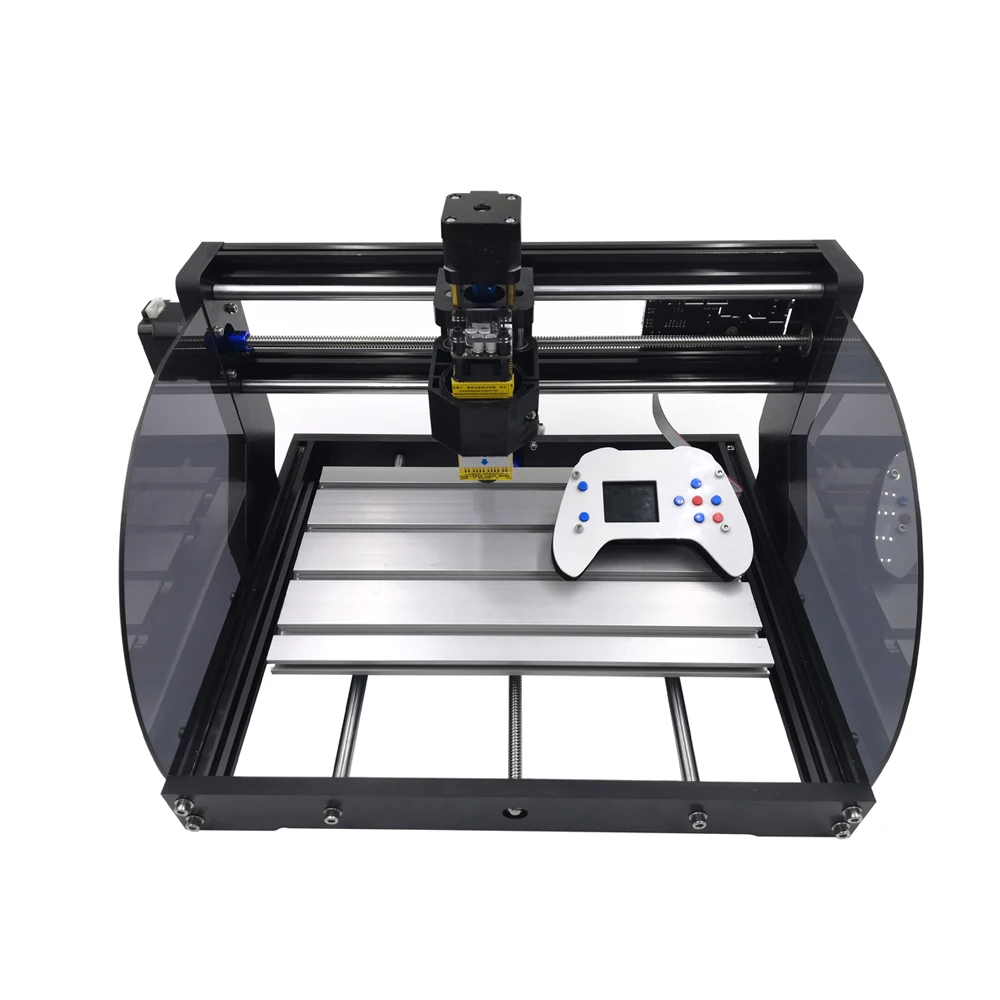

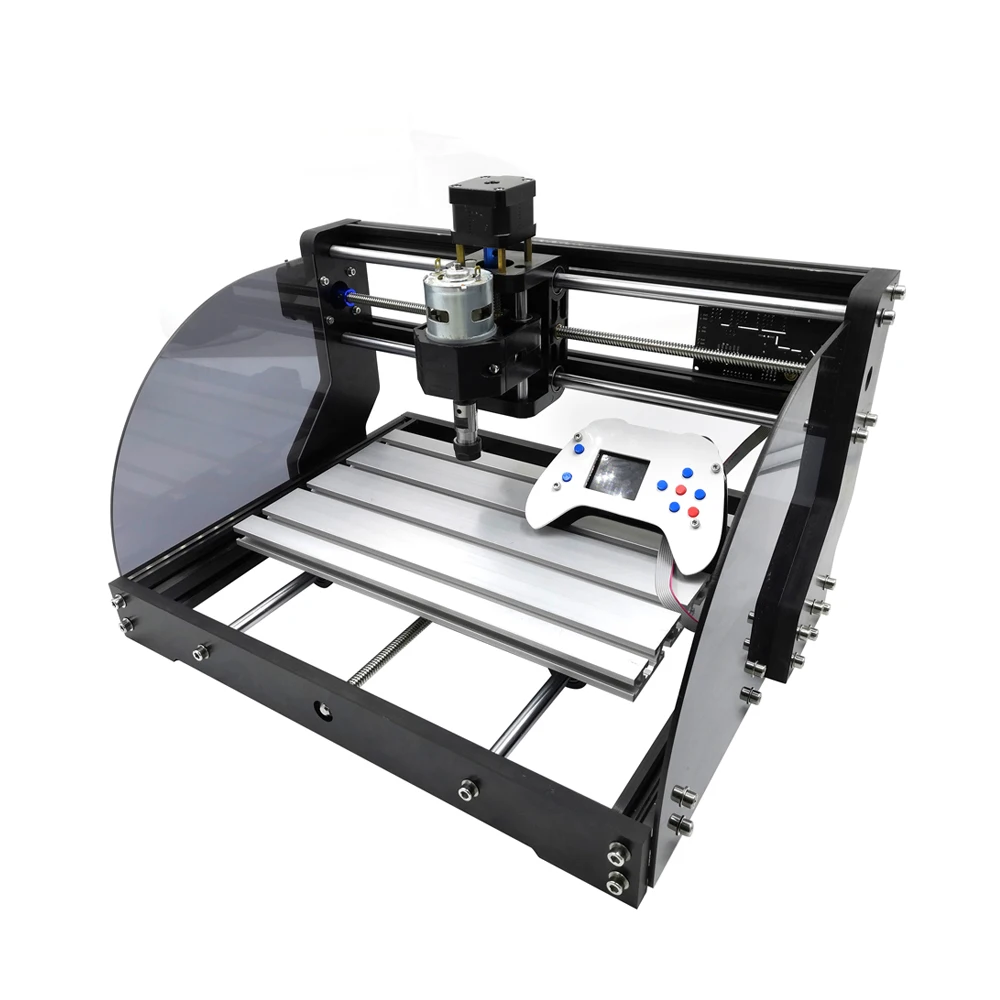

- Model Number: CNC 3018 Pro Max

- CNC or Not: CNC

- Is Smart Device: YES

- Input Power: 100W

- Spindle power: 80W

- Working area: 300 mm*180 mm*45 mm

- Spindle Collet: ER-11 1-7mm

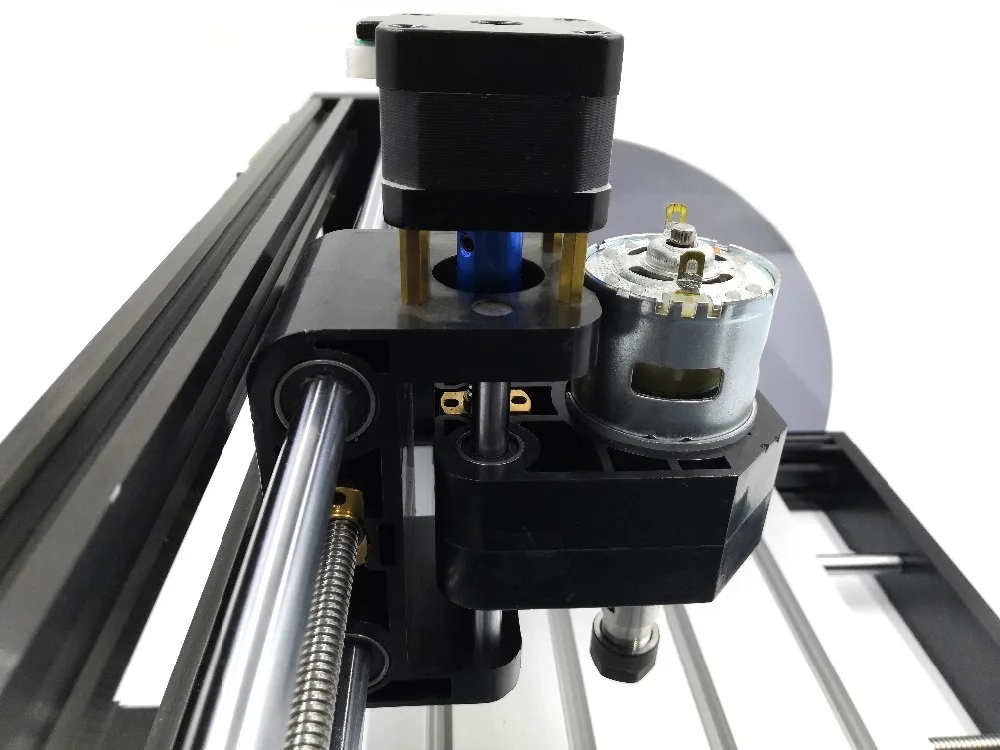

- Spindle: Air Cooling

- Warranty: 12 Months

- Spindle Speed: 10000RPM

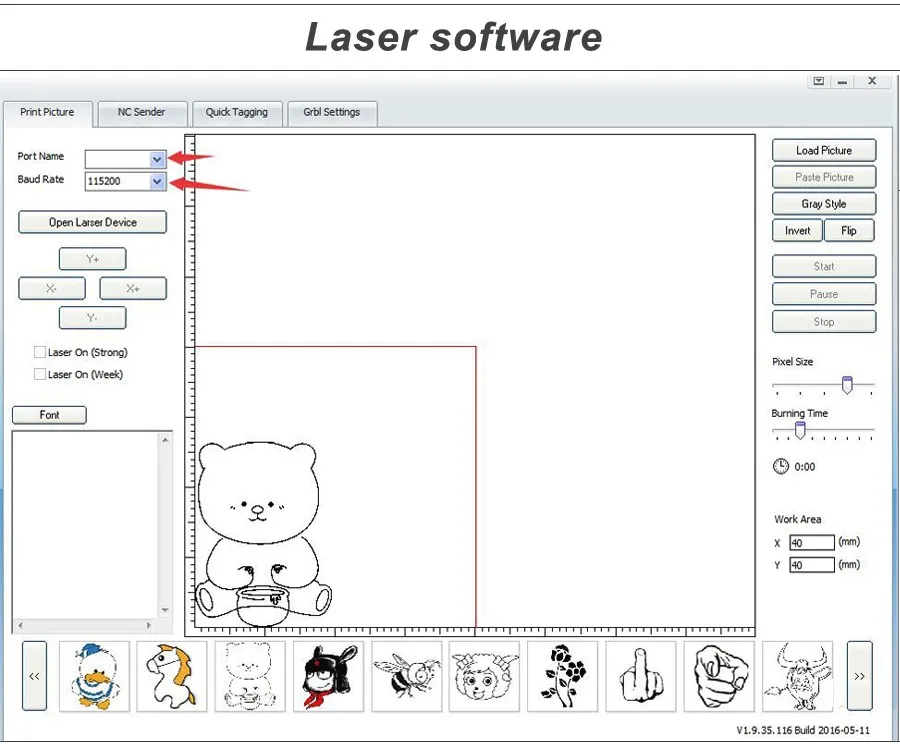

- Software: GRBL / LaserGRBL etc

DIY CNC 3018 PRO MAX Laser Router Engraver Machine with 500MW 2500MW 3500MW 5500MW 15W Module

- Control board:Three-axis drive, dual Y-axis

- Laser:Support offline laser output 2P / 3P, Support PWM TTL function

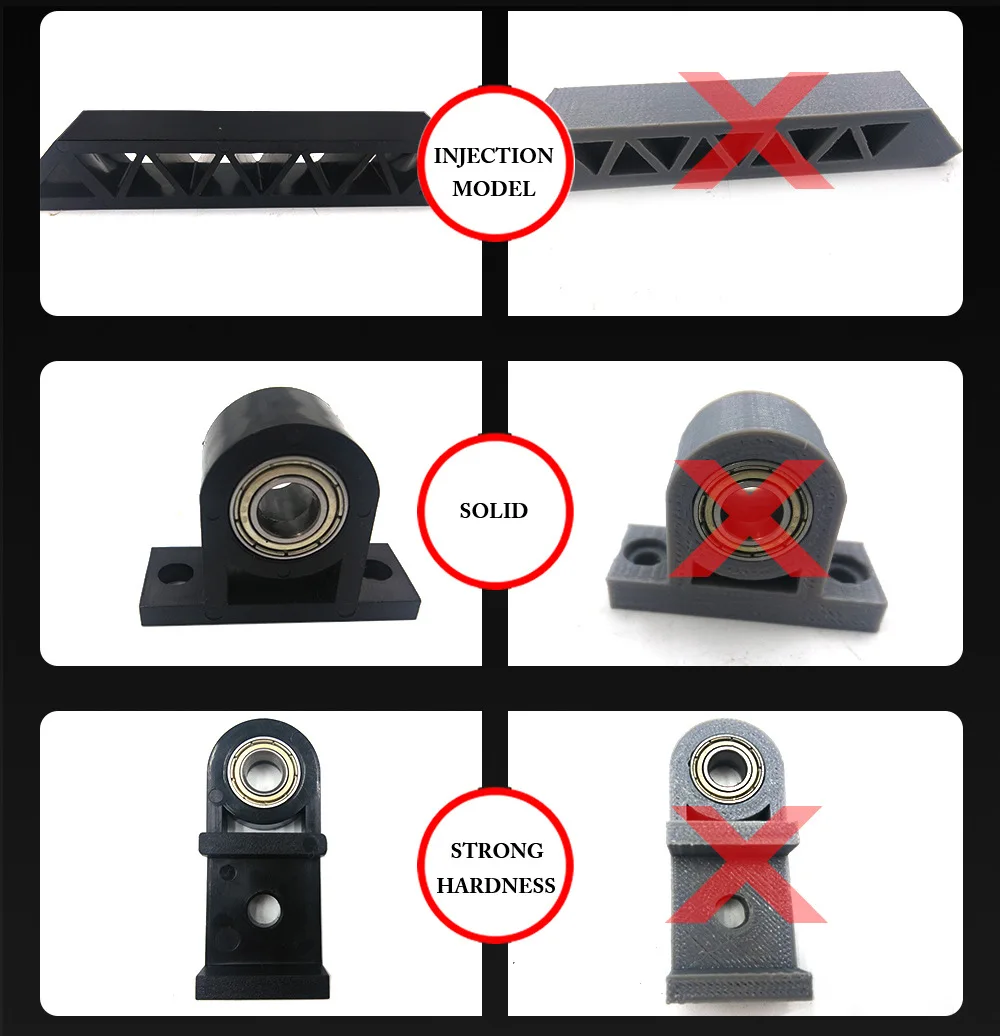

- PVC Frame: Durable, beautiful appearance, high precision and long life

| Control Software | GRBL,LaserEngraver,EngraverMaster etc |

| Construction | Aluminum + BAKELITE |

| Working area | 300x180x45mm |

| Frame size | 400x330x240mm |

| Input voltage | AC 100V-240V,50 / 60Hz (EU/US Plug Available) |

| Output | 24V 5A |

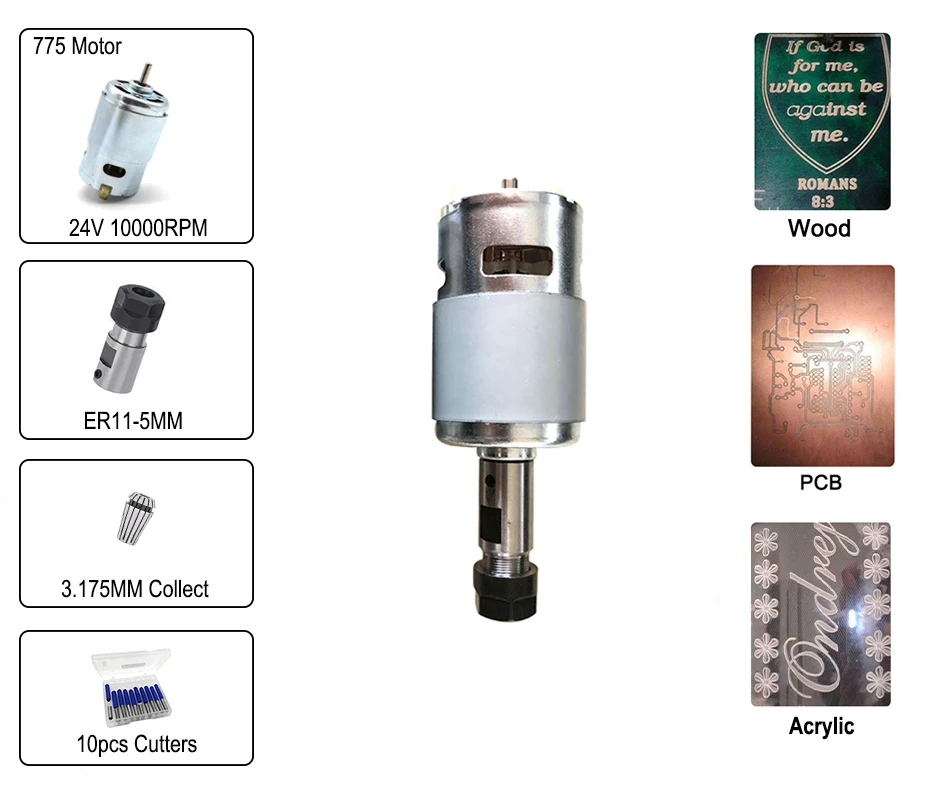

| Spindle | 775 spindle motor,24V 10000 rpm |

| Stepper motor | 1.3A 0.25N.m |

| System support | Windows XP / Win 7 / Win 8 / Win10 |

| Collet | ER11, default size 3.175mm |

| Drill bits | Diameter: 3.175mm tip: 0.1mm length: 30mm |

| Laser (option) | 0.5W 12V 405nm 2.5W/5.5W/15W 12V 450nm (15W Can engrave on SUS 304 stainless steel) |

Applications

1. Three-axis CNC engraving: wood, plastic, PCB, acrylic, plywood, etc.

2. Laser engraving: wood, plastic, leather, bones, stone, paper, outer casing, etc.

3. 15W laser can engrave metal materials such as SUS 304 stainless steel.

Warranty service

One-year’s warranty,all your after-sales problems under protection.

15-day’s part free warranty,any parts damaged within 15 days after receiving the product will be replaced.

CNC 3018 PRO MAX —Without the white offline controller

CNC 3018 PRO MAX offline —With the white offline controller

Brief introduction

A. What area it can used for?

CNC 3018 router mini CNC milling machine is widely used for different area such as Industry,Technology Research,Advertising Design,Arts Creation,Teaching,Student Project and Hobby Purposes, Building Model Making, PCB, Adverstising Signs,Artwork,Crafts,Aircraft Models,RC Model parts,etc.

B. What materials it can used for?

It can work for Wood, acrylic,plastic,Jade, PCB ,PVC Advertising Signs, Artwork, Crafts, Aircraft Models, RC Model parts, Industrial or Hobby Prototype Building, Building Model Making, etc. So, you can do engraving work at office or home,Ideal for milling, engraving, drilling & cutting.

- Upgraded 500mW/ 2500mW/ 3500mW / 5500mW/ 15W Laser Module

- Upgraded Blue-violet laser module, which is 33mm, 3P connection, supports PWM/TTL, power 0-100% adjustable.

- Laser wavelength: 445nm-450nm blue laser

- Drive mode: external ACC constant current drive

- Cooling method: forced air cooling

- Operating voltage: 12V DC

- Control interface: 2 * 2.54 (TTL control switch, PWM control power)

- Shell material: aluminum, surface anodized

- Spindle:775 motor,12-36V 10000RPM

- Collect: ER11-5MM, Default size 3.175mm

- 10 pcs mini PCB drill steel tungsten carbide cutters

The advantages of Upgraded Control Board

1. Upgraded A4988 step motor drivers with heat sink and GRBL1.1f firmware of control board, stable performance, overcurrent protection to avoid damage.

2. Upgraded control board also supports limit switch, tool setting, steering gear, cooling fan and other functions, supports full-line offline engraving, offline tool setting and engraving.

3. Improved power interface: the original plastic interface changed to all metal shielded interface.

4. USB interface: plug-in type, very strong(The old USB interface is patch soldering, collision and improper use easy to drop.)

5. Improved spindle drive increases the isolation of the optocoupler, so that the control board generates less heat, the spindle speed adjustment is more linear and safe.

5. The stepper motor driver adds a self-recovery fuse. When a short circuit or fault occurs, the power will be cut off and the fault indicator will be displayed.

6. 12V step-down increase the self-recovery fuse, when a short circuit occurs, the power can be cut off in time to avoid damage.

7. Optimize the layout, the control area is separated from the drive area, and the operation is more stable.

8.Added heat sink to avoid burning the control board or the offline controller

Offline controller : USB Connection, 1.8in LCD screen with installed SD card

About software and instructions

A 4GB USB Flash Drive includes software and installation instructions along with the package.

You can also download from our Web Cloud Disk(We’ll send you after shipment).

Or tell me your email address, we’ll send you the software and installation instructions.

F.A.Q:

1 Q: Does this machine need to be assembled when I received it?

A: This machine comes as a kit. You need to assemble it yourself. All tools and part are included

in the kit.

2 Q: How to assemble the kit?

A:We’ll provide whole assemble and operating manual,please share your email address,then we’ll send to you.

3 Q: Are there software and instructions can I get it?

A:You can get the software with machine which is a CD ,contact us for instructions.

4 Q: And what image format the software supports? Engrave Mode?

A: Supported Image Format: jpg, bmp, svg, G-code

Supported Engrave Mode: Photo, Word, Scan, Outline, Pixel Laser Engraving

5 Q: Whick type computer system can run its software?

A:The software only support the Windows XP/7/8/10.

6 Q: What’s the laser’s lifetime?

A: The laser module have over 6,000 hours lifetime.

7 Q: What material can it engrave?

A:Wood, bamboo, plastic, paper, leather, rubber,MDF.

8 Q:What material can it cut?

A:wood, paper, thin leather.

9 Q:Can I use it to cut or engrave on metal?

A:It can not engrave or cut on any metal.

10 Q: Can I regulate the laser power or the laser power is adjustable?

A: Sorry that the Fixed laser power is not adjustable, but the engraving speed is adjustable.

11 Q: How long can the machine work continuously?

A: It can work continuously about 45 minutes, after the laser mould cool down(about half of an hour), then start work again. Long time work continuously with shorten the laser module lifetime.

12 Q:My laser doesn’t work, what should I do?

If the machine does not work, it might because:

A The wire connection is wrong.Please check the connection like the picture shown.

B Your computer could not support the software.Please use Win XP 7/8/10 to check it.

C Software problem .Please check whether wires are inserted rightly. And then check your data setting.

D The kit misses some accessories. Please compare with the instruction and tell us, we will solve it once you send us the email.

E Laser module/ driver board/power supply is broken.

Please check which part is the main problem, and then send us a video to prove it.

Or you can send us a video about your software setting, working laser and driver board. We will analyze it and give you a solution.

Reviews

There are no reviews yet.