Description

- Brand Name: ACCTEK

- Origin: CN(Origin)

- Certification: CE

- Condition: New

- Model Number: AKJ1325F

- CNC or Not: CNC

- Product name: Fiber Laser Cutting Machine For Metal 500w

- Cutting Thickness: 0-20mm

- Cutting Area: 1300*2500mm

- Cutting Speed: 35m/min

- Control Software: Au3tech /Cypcut optional

- Certification: CE, ISO, FDA

- Laser power: 500w/750w/1000w/2000w/3000w

- Driving system: Japanese Yaskawa/ Panasonic servo motors optional.

- Laser tube type: Import/Chinese Fiber Laser

- Warranty: 2 years

1000w laser cutter fiber metal cutting laser raycus fiber laser cutting machine for Carbon steel copper

Standard Configurations of laser cutting

§Working area:1300*2500mm

§Seamless welded steel structure

§500W Raycus laser generator

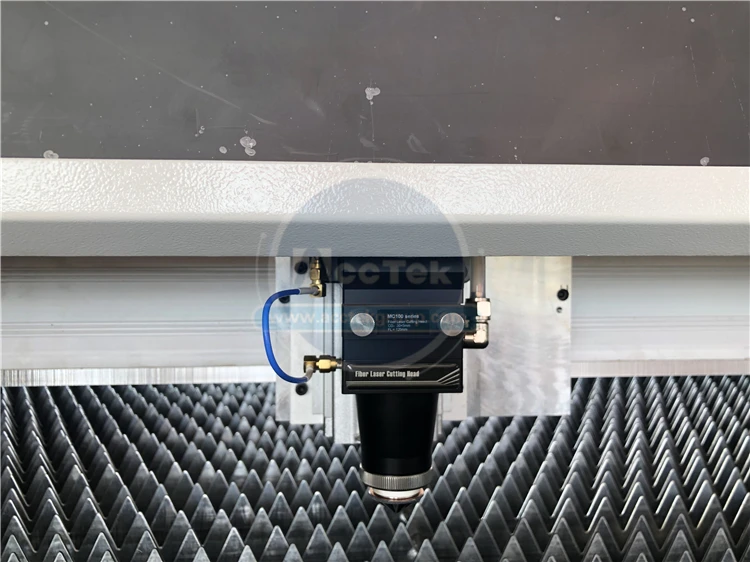

§Good quality Au3tech cutting head with auto following system

§Au3tech controller system

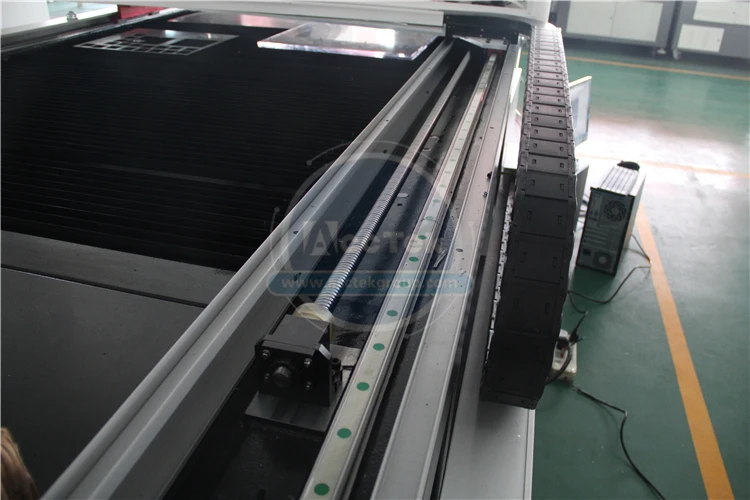

§Taiwain Hiwin 25mm square guide rails

§High precision Taiwn TBI ball screw transmission

§Taiwan Delta servo motor and driver: 750W for X Y axis, 400W for Z axis

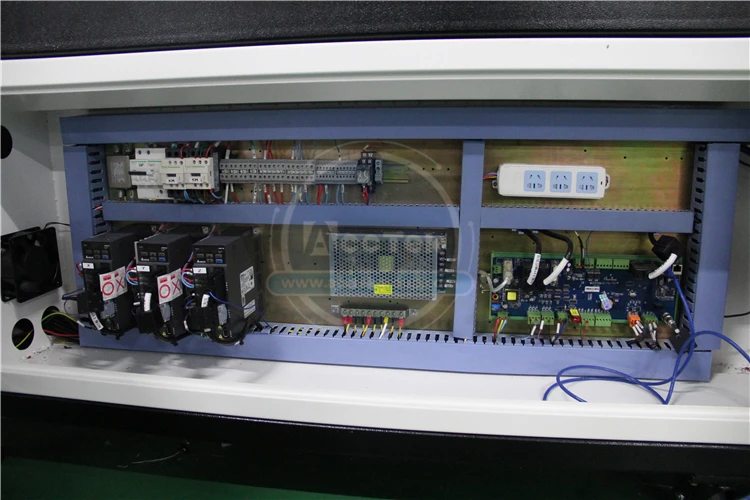

§French Schneider electronic components

§Taiwan Airtac pneumatic element

§Industrial water chiller

§Computer included

§Standard wooded box

Optional Configurations oflaser cutting

§Laser power

§Extra head with co2 laser tuber for cutting nonmetal materials

Main Features oflaser cutting

§Excellent beam quality:The focused spot smaller cut lines more sophisticated, higher productivity,

better quality and processing.

§High cutting speed:2 times faster than the same power CO2 laser cutting machine.

§High stability:Adopts the world's top imported Fiber laser, stable performance,

a key component of up to 100,000 hours life.

§High electro-optical conversion efficiency:Fiber Laser cutting machine is three times higher than

the CO2 laser Electrical and optical conversion efficiency, energy saving and environmental protection.

§Low cost:The whole power consumption of only similar CO2 Laser cutting Machine 20-30%

§Low maintenance cost:No working gas lasers; optical fiber transmission, withoutreflecting lenses;

can save a lot of maintenance costs.

§Easy operation and maintenance:Optical transmission, no need to adjust the optical path.

§Super flexible light guideeffect:Small size, compact structure, easy to flexible processing requirements.

Technical Parameters oflaser cutting

|

1 |

Model |

AKJ1325F |

|

2 |

Working area |

1300*2500mm |

|

3 |

Laser power |

500W/750W/1000W |

|

4 |

Control System |

Au3tech |

|

5 |

Transmission |

Taiwan TBI ball screw transmission |

|

6 |

Guide rail |

Taiwan HIWIN linear guide rail |

|

7 |

Motor |

Taiwan Delta servo motor |

|

8 |

Electronic Components |

French Schneider |

|

9 |

Max Speed |

20m/min |

|

10 |

Repeat positioning accuracy |

±0.03mm/m |

|

11 |

Maximum Acceleration |

0.5G |

|

12 |

Min line width |

0.1mm |

|

13 |

Graphic Format Supported |

AI, BMP, DST, DXF, DXP, PLT |

|

14 |

Cooling Way |

Water cooling |

|

15 |

Machine Operating temperature |

0 ℃ -40 ℃ |

|

16 |

Power Requirements |

220V/380V, 50/60Hz |

|

17 |

Dimensions |

4030*2160*1790mm |

|

18 |

Weight |

1450kg |

Detail Images ofDetail Images oflaser cutting

Application Materials oflaser cutting

The fiber laser cutting machine is suitable for metal cutting like stainless steel sheet, mild steel plate,

carbon steel sheet, alloy steel plate, spring steel sheet, iron plate, galvanized iron, galvanized sheet,

aluminum plate, copper sheet, brass sheet, bronze plate, old plate, silver plate, titanium plate, metal

sheet, metal plate, tubes and pipes, etc.

Application Industries oflaser cutting

This fiber laser cutting machine is widely used in manufacture billboard, advertising, signs, signage,

metal letters, led letters, kitchen ware, advertising letters, sheet metal processing, metals components

and parts, ironware, chassis, racks & cabinets processing, metal crafts, metal art ware, elevator panel

cutting, hardware, auto parts, glasses frame, electronic parts, nameplates, etc.

§We accept Western union, Moneygram, TT, Trade assurance of Alibaba,

and you can pay 30% in advance, 70% before delivery.

§The machine will be produced after received your deposit, its need about 15-25 working days

to produce the machine after getyour deposit.

§After the machine is ready, we will test it very carefully, and ensure everything is OK.

§Then we will show you the machine photos and the testing video.

§After you agree, please finish the balance.

§Finally, all things are tested well, then we arrange the delivery.

Pre-sale services

§Provide the free consultation of the equipment .

§Provide the standard device and the flow chart.

§According to the clients’ special requirement, offering the reasonable plan

and free design helping to select the equipment.

§Welcome to visit our factory.

Services during the sales

§Inspect the machine before leaving the factory.

§Oversea install and debug the equipment

§Train the first-line operator.

After sale services

§24 hours online service.

§Provide the VIDEO with Install and debug the equipment.

§Provide technical exchanging.

Service In Life-Time: No matter how many years passed, you always can contact me,

we can give you any technical support in the future life-time.

Monica YangMob&whatsapp:+86-18369950802Email&Skype:export05@acctekcnc.comJinan AccTek Machinery Co.,Ltd

Reviews

There are no reviews yet.