Description

- Brand Name: ACCTEK

- Origin: CN(Origin)

- Certification: CE

- Condition: New

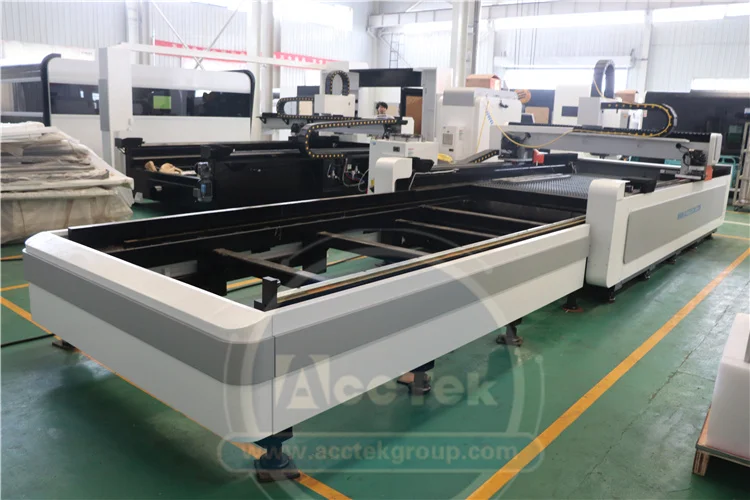

- Model Number: AKJ1530FC

- CNC or Not: CNC

- Product name: 1530 Cutting Machine Fiber Laser

- Key words: Raycus Fiber Laser Cut

- MOQ: 1 set

- Laser Type: FIBER LASER

- Cooling Mode: WATER COOLING

- Engraving Area: 1500mm*3000mm

- Driving System: XY axis Yaskawa 850w, Z axis Pansonic 400w

- Control system: Cypcut

- Transmission: Rack and pinion

- Graphic Format Supported: AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

Laser Cutting Machine Fiber 1000w Light Source Fiber Optic Laser 1530 Fiber Laser Steel Cutting Machine

Main features:

# With automatic exchange table, more convenient.

# High speed, high precision, high efficiency and low cost.

# Easy on operation, fiber optical path, without tedious adjustment on the optical path.

# Compact structure, good sealing, strongly adaptable to changes in the environment.

# With automatic nesting system which can save time, save the materials, sheet utilization ratio up to 95%.

# Moving crossbeam, high precision racks and linear guide rail, stable transmission, high precision.

# Using professional and powerful Shanghai Cypcut fiber cutting controlling system based on Windows operating system, with good Human-Machine Interaction and easy operation.

# Heavy duty frame 5000kg, crossbeam and worktable adopt integral welding structure. With stress relief annealing and vibration stress relief treatment,

it can completely eliminate the welding and processing stress, maintaining high strength and precision, keeping the normal use of 20 years without deformation.

Application:

1. Application industry.

Ship Building, Construction Equipment, Transport Equipment, Aerospace Industry, Bridge Building, military industrial, wind power, Structural Steel, Boiler containers, Agriculture Machinery,

Chassis electrical cabinets, Elevator manufacturers, Textile Machinery, Environmental protection equipment,Aerospace technology, rocket, plane, robot, elevator,

steamship and automobile manufacturing and metal parts processing industry for metal plate, advertisement, kitchen ware, bit tool, hardware etc.

2. Application materials.

Our fiber cutting machine can work on the following materials : steel, copper, aluminum and stainless steel can be processed.

Applies to iron plate, aluminum plate, galvanized sheet, White Steel plate, Titanium plates, and so on like the sheet metal.

|

Working area |

1500*3000mm |

|

Control System |

Cypcut controller |

|

Guide rail |

Taiwan HIWIN linear guide rail |

|

Transmission |

Rack and pinion transmission |

|

Electronic Components |

French Schneider |

|

Motor |

X-axis Japanese Yaskawa servo motor 850w Y-axis Yaskawa servo motor1800w Z axis Panasonic servo motor400w |

|

Max Cutting Speed |

Depend on power and materials |

|

Repeat positioning accuracy |

±0.01mm |

|

Maximum Acceleration |

0.5G |

|

Min line width |

0.1mm |

|

Power Requirements |

220V/380V, 50/60Hz |

|

Cooling Way |

Water Cooling |

|

Machine Operating temperature |

0 ℃ -40 ℃ |

|

Graphic Format Supported |

AI, BMP, DST, DXF, DXP, PLT |

Details of fiber laser cutting machine:

1) Raytools laser cutting head.

Highly dust-proof: the dust-proof grade is IP65, and the light path is fully enclosed, so the possibility of lens contamination is almost zero.

Efficient water cooling: The focusing lens, collimating lens and nozzle have built-in cooling function, which can solve the problem of cutting heating.

2) Cypcut controller software.

Advanced technology, suit for all kinds of metal materials cutting.

Automatic optimization of imported graphics, Concise and clear process settings, For the use of machine tools, it can provide rich and timely statistics. Accurate edge finding aid.

3)Yaskawa servo motor.

Faster speed with signal feedback .Low heat radiation. Run smoothly at ultra-low speed. Simple operation, excellent stability, high-speed,high-precision processing can be achieved,even if the machine has not been replaced for many years or the equipment has different differences,there will be no oscillation,and stable operation can be achieved.

4) Raycus Laser Source

Fiber laser is compact in structure, stable in performance and widely used, Fiber laser has high photoelectric conversion efficiency, good beam quality and low maintenance cost,(Germany IPG Laser source is optional)

5) Industry Water chiller

Dual temperature fiber chiller is used to cool both the fiber laser and the QBH connector. Users can manually set water temperature control working mode according to actual needs.

6) French MOTOVARIO reducer

High performance, wide application, high rigidity, high efficiency, low noise and low backlash.

7) Aviation Aluminum Gantry

light weight, high strength, no deformation. Molded and framed by integral steel mold and die-casting technology, light crossbeam enables equipment a high operation speed, improving processing efficiency and processing quality.

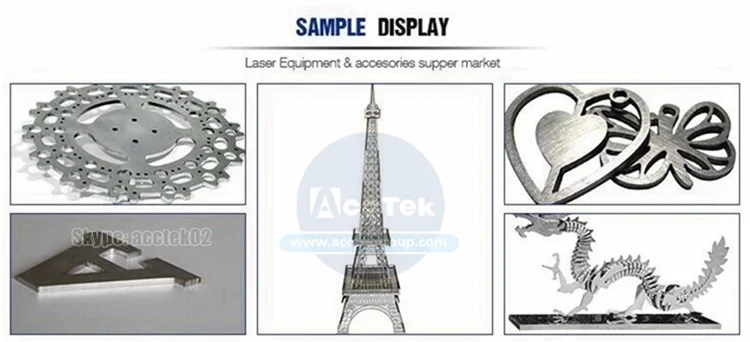

Samples:

Aftersale Service :

1. 24 months guarantee of the whole machine, including fiber lase generator.

2. Main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

3. Lifetime maintenance free of charge.

4. We will provide the consumable parts at a factory price when you need replacement.

5. Machine has been adjusted before delivery.

6. Our technician can be sent to your company to install or calibrate if necessary.

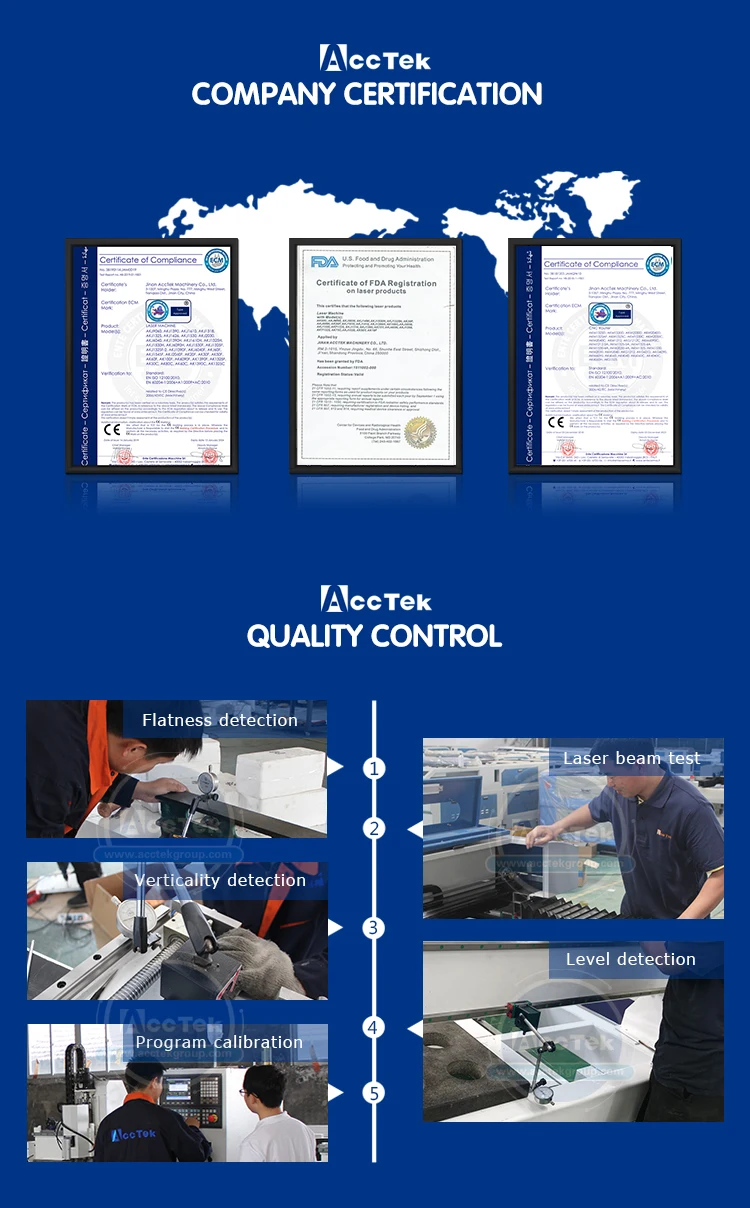

About us:

FAQ:

Q1. Before send me an inquiry on our cnc laser, it is better for you to provide me the following information:

1) Your metal or non-metal material size. Because in our factory, we have different models according to working area.

2) Your materials.

Metal/Acrylic/Plywood/MDF, etc?

3)You want to engrave or cut?

If cut,could you tell me your cutting thickness? Because different cutting thickness need different laser tube power and laser power supplier.

Q2. If we don't know how to use the machine, can you teach us?

Yes. We will send you manual and guide video in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by "Teamviewer" online help software. Or we can talk by phone,email or skype.

Q3. How long is the delivery time?

For standard machines, it would be 10-15 days; For non-standard machines and customized machines according to client's specific requirements, it would be 15 to 20 days.

Q4. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory. Our machine passed CE Certificate, meet European and American standard, already exported to more than 100 Countries.

Q5. Do you arrange shipment for the machines?

Yes. For CIF or DDU DAp price,we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

Contact us:

Name : Winnie Xu

Mob&Whatsapp: +86-19862191443

Wechat: 13165291807

Skype:export37@acctekgroup.com

E-mail:export37(at)acctekgroup.com

Reviews

There are no reviews yet.