Description

- Brand Name: HKNA

- Origin: CN(Origin)

- DIY Supplies: ELECTRICAL

- Certification: CE

- Place of Origin: Guangdong, China

- Application: MILLING MACHINE

- Condition: New

- Video outgoing-inspection: Provided

- Machinery Test Report: Provided

- Marketing Type: Ordinary Product

- Brand Name: ly

- Warranty: 1 Year

- After Warranty Service: Online support, Field maintenance and repair service

- Certification: CE

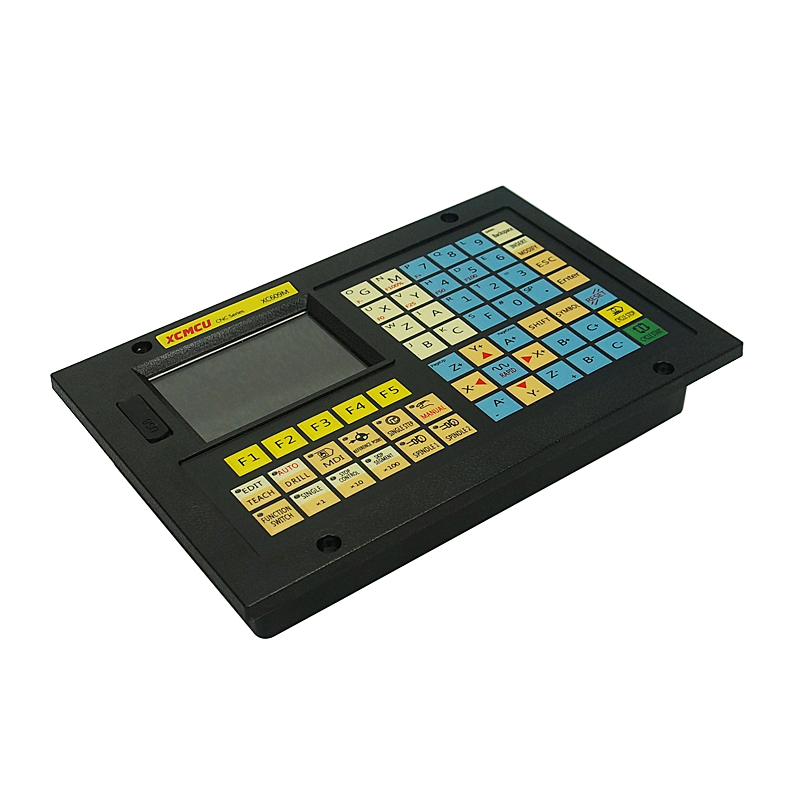

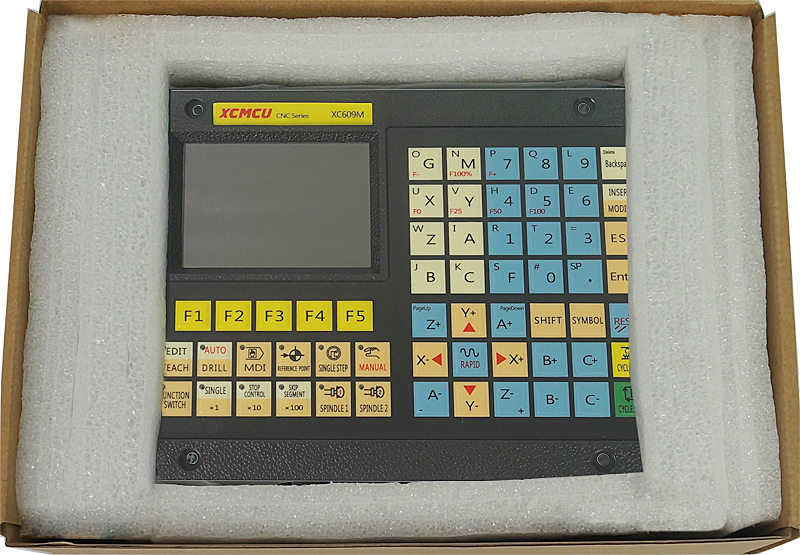

CNC Controller XCMCU XC609M single 1-6 axis linkage CNC system Various machine application super function 24V

-

producing

area: chinese mainland -

brand: XCMCU

-

model: XC609M

-

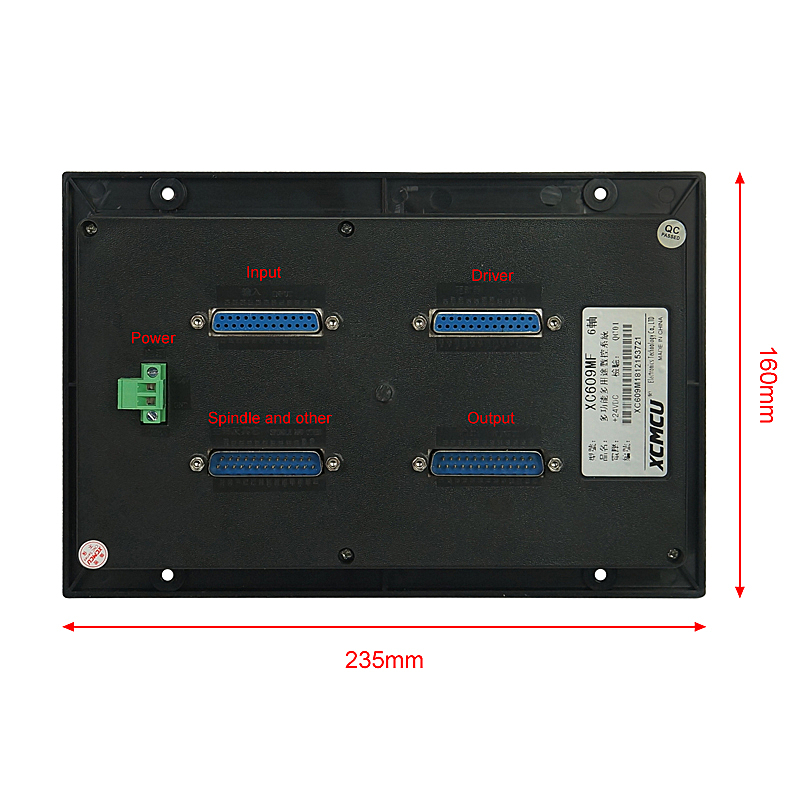

voltage: 24V

-

Power

mode: direct current

Note:

The link is a multi model product. If the

details are incomplete or not in conformity with the model you purchased,

please use the manual in kind, thank you!

XC609MAis 1 axle

XC609MBis 2 axle

XC609MCis 3 axle

XC609MDis 4 axle

XC609MEis 5 axle

XC609MFis 6 axle

1.1introduction

XC609M multi-purpose multi-purpose CNC system for my

company developed a new generation of CNC system. Support milling, boring,

attack, drilling and automatic feeding. Using 32-bit high-performance

microprocessors,the use of real-time

multi-task control technology and hardware interpolation technology, full

linkage, 0.001mm interpolation accuracy, speed 12 m / min. It is the choice of

CNC drilling machine, CNC milling machine, special machine tool, automatic

equipment, automatic welding robot, feeding robot, coordinate robot and so on.

XC609M CNC system hardware and software features:

Based

on 32-bit microprocessor, full linkage, 0.001mm interpolation accuracy, speed

12 m / min.

Can

run three programs (1 main program, 2 subroutines), to facilitate processing,feeding, cutting procedures for the

preparation.

Using

3.5-inch color widescreen LCD, resolution 480X320, Windows interface style.

Equipped with five soft function keys,easy to learn. Provide parameter classification,

alarm log, system diagnostics and other rich display interface, easy debugging

and maintenance.

Standard

G instruction,compatible with FANUC

system instructions.

40

G instructions that support drilling cycles,tapping cycles.

Part

program full-screen editing, built-in 128M massive program space, can store N

parts program.

With

USB interface, support U disk file read and write, data backup.

Input

24 (expandable to 96) points, output 24 (expandable to 96) points (custom),

flexible and convenient.

Chinese

/ English operation interface, complete help information, operation more

convenient.

The

system uses interpolation before acceleration and deceleration control.

Support

multi-level operation authority,convenient

equipment management, with time-limited system lock function.

Supports

third-party software G code files.

1.2Technical

specifications

|

basic skills |

|

|

Control the number of axes |

1~6 roller(X,Y,Z,A,B,C) |

|

Number of linkage axes |

Full linkage |

|

Analog spindle |

2 |

|

Spindle monitoring |

exist |

|

Small command unit |

0.001mm |

|

Large command value |

±99999999×Small |

|

Rapid feed rate |

12000mm/min |

|

Fast feed rate |

F0, 25%, 50%, 100 |

|

Cutting feed rate |

12000mm/min |

|

Feed rate override |

0~150% |

|

Electronic gear ratio |

1~65535: 1~65535 |

|

Automatic acceleration and deceleration |

exist |

|

location |

G00 (Can be linear interpolation positioning) |

|

runin |

straight line(G01),arc(G02/G03/G12),Helix interpolation |

|

Return to reference point |

Automatically return to the reference point(G28) |

|

LCD |

3.5 inch TFboysT LCD screen with a resolution of 480 * |

|

MDI Soft key |

5 |

|

Single step feed |

x1,x10,x100 |

|

communication interface |

U disk interface |

|

External handwheel interface |

exist |

|

I/O port |

24/24(open end to 96/96) |

|

pause(s) |

exist |

|

Quasi-stop state |

Exist |

|

Quasi-stop |

Exist |

|

Storage trip check |

exist |

|

MDI revolve |

exist, Support multi-segment operation |

|

restoration |

exist |

|

Jump switch |

exist |

|

Single run |

exist |

|

Program protection switch |

exist |

|

Self-diagnostic function |

exist |

|

Emergency stop |

exist |

|

power |

DC24V |

|

coordinate system |

Machine coordinate system(G53),Workpiece coordinate system(G92,G54~G59),Local coordinate system(G52),Coordinate system plane |

|

Automatic coordinate system setting |

exist |

|

Decimal point input |

exist |

|

Auxiliary function |

|

|

Auxiliary function |

M2 bit, M code custom, manual / MDI / automatic mode |

|

Spindle function |

|

|

Spindle function |

twin spindles |

|

tapping |

support |

|

Spindle analog output |

exist, twin spindles |

|

Tool function |

|

|

Tool function |

Support points in the knife, three set the center of |

|

Tool compensation memory |

-9999.999~9999.999,99 |

|

Cutter Compensation |

Each axis length compensation |

|

Edit operation |

|

|

editional function |

Parameter, diagnostic bitwise input, program editing, |

|

memory capacity |

128M |

|

Number of stored programs |

N |

|

The display of the program name |

Chinese, English, numbers, combinations |

|

Program line lookup |

Exist |

|

Skip optional blocks |

Exist |

|

sequence switch |

exist |

|

display |

|

|

display |

Chinese, English |

|

Processing time, number of parts display |

exist |

|

Spindle speed, M / S command |

exist |