Description

- Certification: CE

- Origin: CN(Origin)

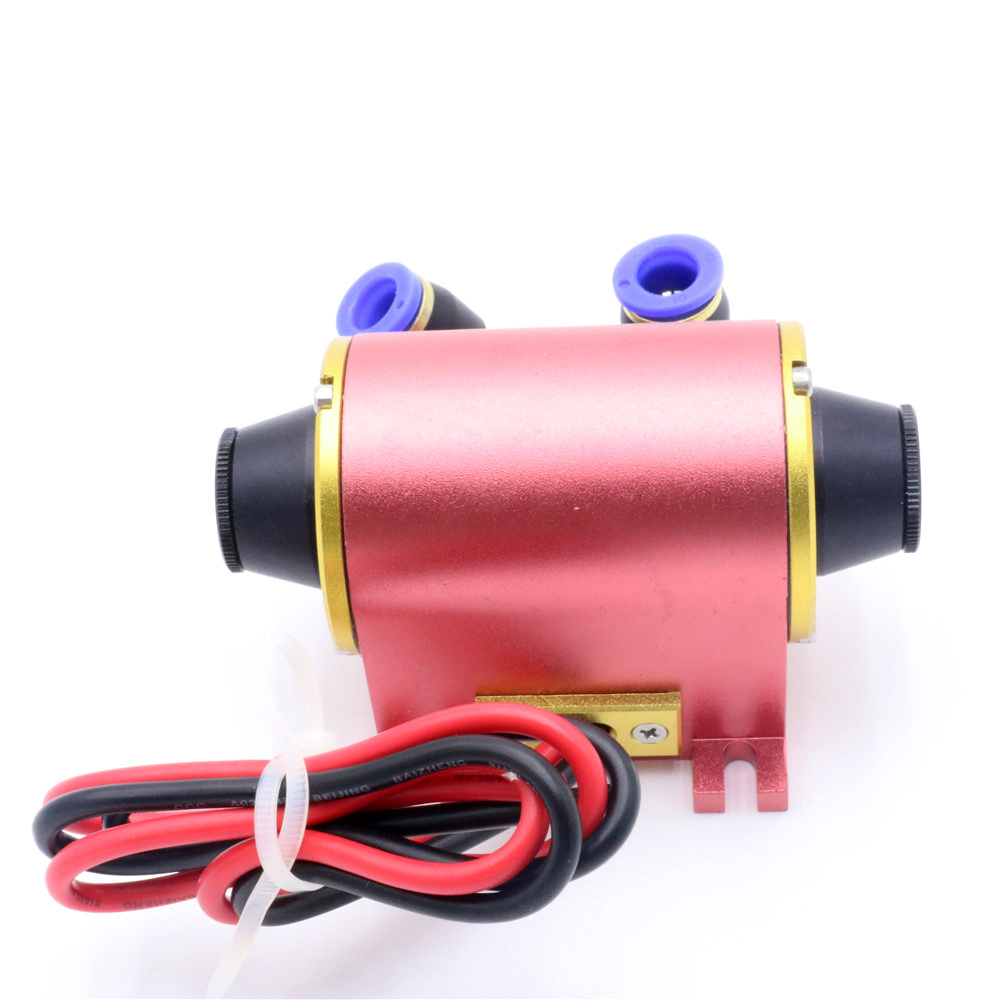

- Model Number: GTPC-50S

GTPC-50S Diode Pumped Laser Module 50W Beijing Origin for Laser Marking Machine Warranty 1 Year

GTPC-50S

SN: XXXX

1. Technical parameters

CW Output Power: 50W

Threshold Current: ~6A

Operating Current: ~18A

Forward Voltage: ≤18V

Center Wavelength: 1064nm

The length of the YAG rod:65mm

The Diameter of the YAG rod:3mm

YAG Terminal: Flat/AR at 1064nm/YAG doped 1%

The cooling water flux: 4-5L/min

Cooling power: >100W

Optimum temperature: 20°C

Temperature Range (Storage): -20°C~ 70°C

2. Typical Performance Curves

Note: Testing conditions

1. The length of the cavity is 170 mm;

2. The transmission of the output mirror is 20%.

3. The temperature of the chilling water is determined by the optimized result, each module has recommended optimum temperature.

The output power can be changed while the cavity length, the output transmission or the temperature of the chilling water is changed.

Section 1 User Safety

Section 2 Initial Inspection

Section 3 Product Description

Section 4 Specification

Section 5 Installation and Using Method

Section 6 Trouble Shooting

Section 1

User Safety

GT Optics laser modules are infrared laser sources. The energy emitted is invisible to the human eye. These products emit radiation in 1064nm. Please pay attention to the mark on this product, do not look directly at the laser output window (cross-section of the output beam).

Please do not expose output laser beam to a plane mirror or other reflective surfaces, reflected beam may make people injured or damage other objects .

The user should wear laser goggles.

If this product is used in the laboratory, there should be laser warning marks in this laboratory.

If the user wants to check the quality of laser spot, please use a wavelength converter or check attenuated laser spot with CCD.

Section 2

Initial Inspection

Upon receipt, carefully inspect the shipping container for damage. Carriers will not accept claims for damage unless all shipping materials are saved.

Read this manual before connecting a laser driver to the GTPC-50S.

Section 3

Product Description

The laser module is an ideal building block in the development or production of medium power rod laser systems, conversion of existing lamp-based laser designs to diode-pumping, or retrofit of existing arc lamp hardware to provide more stable and reliable operation.

It incorporates a Nd:YAG laser rod that is efficiently pumped by a radial array of long life laser diode bars, and delivers excellent gain uniformity and lensing performance. It is ideally suited for multimode applications such as laser marking, and can also provide high beam quality for more precise micro-machining and scientific applications.

The laser module is driven by low voltage electronics. Cooling of the laser is accomplished with a simple recirculating water chiller running on filtered water, eliminating the need for deionized water systems.

Section 4

Specification

1. Technical parameters (working temperature of the chiller: optimum temperature (refer to the parameters table)

CW Output Power: 50W

Threshold Current: 6A

Operating Current: 18A

Forward Voltage: ≤18V

Center Wavelength: 1064nm

The length of the YAG rod: 65mm

The Diameter of the YAG rod: 3mm

YAG Terminal: Flat/AR at 1064nm/YAG doped 1%

Weight: ≤1.5kg

Recommend Case Temperature of chiller: 19-23°C

Temperature Range (Storage): -20°C~ 70°C

2. Typical Performance Curves

Note: Testing conditions

1. The length of the cavity is 170 mm;

2. The transmission of the output mirror is 20%.

3. The temperature of the chilling water is determined by the optimized result, each module has recommended optimum temperature.

3. Mechanical Dimensions

Section 5

Installation and Using Method

1. Air Circumstance

If dusts or impurities adhere to an optical component on the area, high laser energy density can damage this area, such as crystal ends. To prevent dusts from polluting rod ends of the YAG crystal or entering the cavity, clean air or sealing the laser system is necessary.

2. Water cooling system

n Pure water is required. Filtration should be added to the water cooling system. Check water quality routinely, change water or filtrate water immediately when impurities are found.

n We demand that the cooling water flux should be 4-6L/min. Too high water flux may cause non-stabilization of laser spot due to its impact on the crystal. Too low water flux may cause accelerated aging of LD arrays or shortened lifetime of DPL due to insufficient cooling.

n Each DPL has optimum working temperature of cooling water, please set the temperature of the chiller within +2ºC of the optimum temperature, and the control accuracy of water temperature should be within +1ºC.

3. Power Supply

If you use the power supply equipped by our company, please do not connect or disconnect DPL when the power supply is at the status of startup; if you want to use the power supply made by another company or yourself, please contact our company to confirm if it can be used.

4. After uncovering the protective covers on two output windows of DPL, check to see if there is blemish on two ends of the YAG rod, operation cannot be continued unless two ends of the YAG rod are clean.

5. Fix the DPL module on a plane and assemble the resonant cavity designed by the user.

6. Connect water pipes of the chiller to the water outlet / inlet of the DPL module. (The water outlet and water inlet can be exchanged.)

7. Connect the power supply to the DPL module (Connectors: red: + / black: -).

8. Adjust the resonant cavity in the user’s optional mode.

9. Turn on the power supply of the chiller (check to see if there is no water or no adequate water in the chiller), the water flux should be higher than 4L/min; Set the water temperature at desired value. (Each DPL module has recommended water temperature.)

10. Check the water outlet / inlet of the DPL module to make sure that cooling water can flow fluently and without water leakage, then quickly turn on the power supply and adjust working current to no less than 5A, because high humidity or large difference of the temperature inside the module and outside the module may cause dew on internal components, even make them failure.

11. Increase the current, but not higher than 20A. Normally the working current is about 18A when the output power is 50W. Water temperature should be set at 19-23ºC.

12. When finishing using this product, quickly stop running the chiller to prevent dewing on internal components. Reduce the current to zero or press the power-cut triggered switch of the laser power supply, to quickly decrease the voltage of the chiller to zero, then other operation can be continued.

13. Keep water in the chiller clean. To prevent water pipes from aging or being choked, you should change water every 1-2 months. To prevent impurities from choking pipes, you should seal the water inlet / outlet on this product when not being used.

Section 6

Trouble Shooting

1. The output power is lower than the rated power

n Set the output power of DPL at the desired value when the water temperature is equal to the optimum temperature (each module has an optimum temperature–output power value). Adjust the output wavelength of Diode arrays by 0.2-0.3nm/°C.

n Check to see if two ends of the YAG rod and surfaces of the resonant cavity are clean, clean off the blemish or replace the YAG rod, improve the working environment.

n The typical performance is measured with 170mm of the cavity length and 20% of the output transmission, the output power can be changed while the cavity length or the output transmission is changed.

2. Abnormal working voltage

n The working voltage increasing is probably because the power line resistance is too large, please replace it with a thick wire.

n The working voltage decreasing is probably because the LD bar has been breakdown, please contact the manufacturer as soon as possible.