Description

|

Wavelength

|

808nm or up on requirement

|

|

Output power

|

500w up to 10kw

|

|

Operation mode

|

QCW

|

|

Cooling

|

actively cooled/ passively cooled

|

1. Effcient: High output power up into the 4800W.

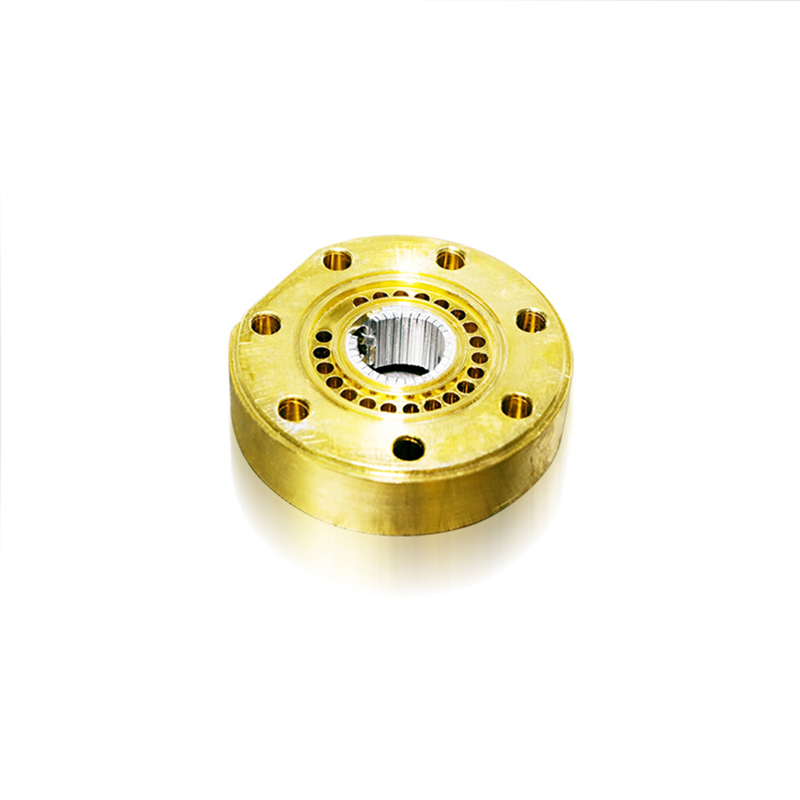

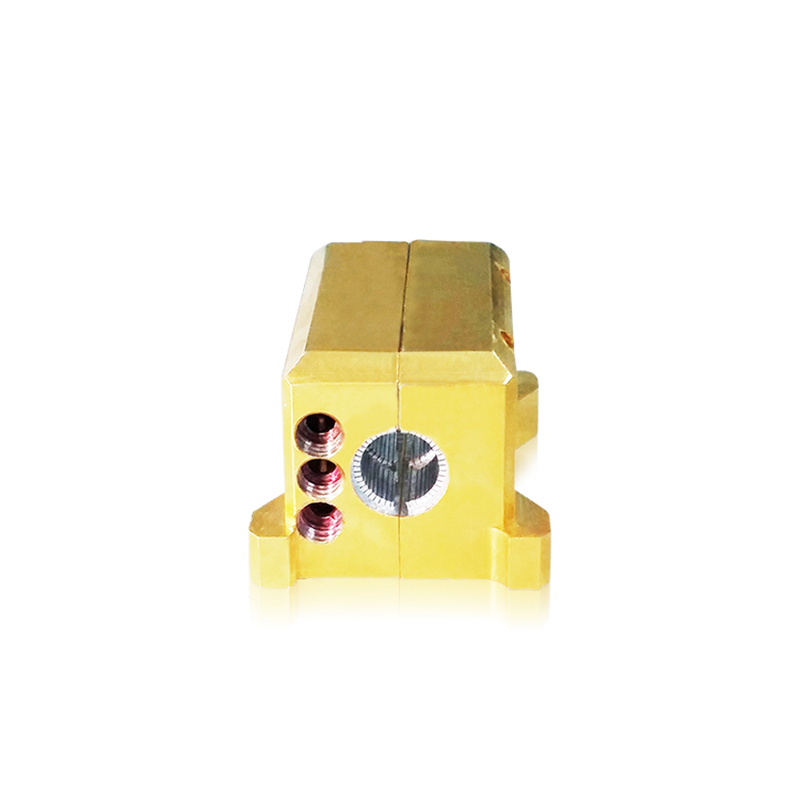

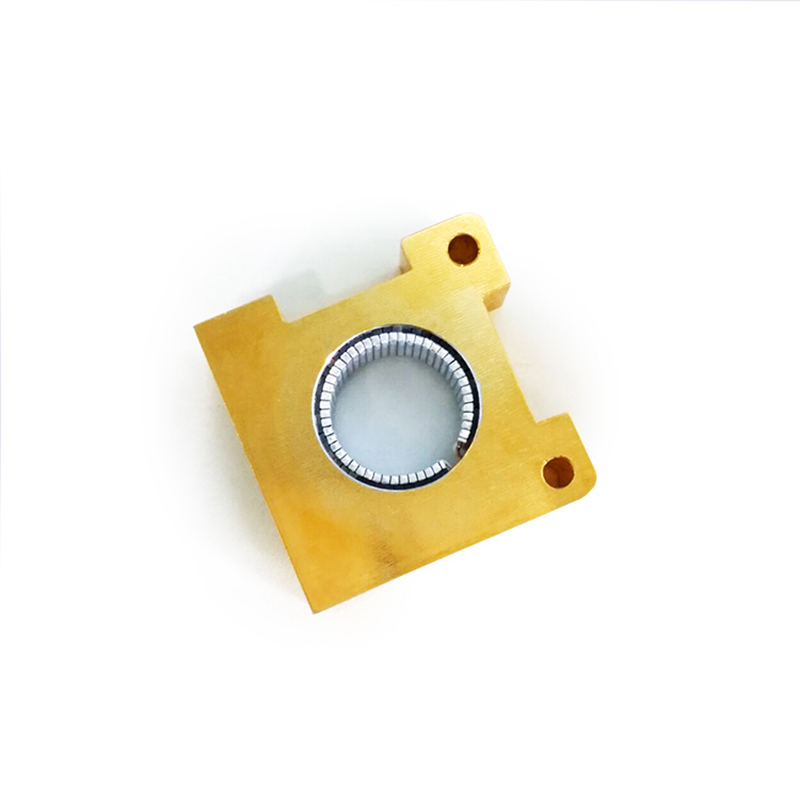

2. Compact: Arc and lightweight design is easily integrated into pump module.

3. Robust: Shock and vibration resistant.

4. Reliable and high-quality: Gold and Tin (hard solder) mounting. Works even under the most demanding climatic conditions.

5. Wavelength combination: beneficial for full temperature pumping design.

1.High energy research: QCW pumping sources for solid-state lasers.

2.Medical technology: Long pulse operation, use in esthetics (epilation) and dermatology.

3.Excitation light source for solid-state lasers in the 1320 nm range for parenchyma surgery.

4.Defense: Short pulse operation, use as a pumping source, for lighting orin LIDAR systems.

5.Industry: Excitation light source for solid-state and fiber lasers.

|

Model ARCQCW-MA-100~500-N

|

||

|

Optical Parameters

|

||

|

Output power (W)

|

QCW 100~500*N

|

|

|

Center Wavelength at 25℃(nm)

|

808

|

|

|

Number of bars in one stack

|

1~20

|

|

|

Bar pitch (mm)

|

0.8~ 3

|

|

|

CenterWavelength Variationat 25℃ (nm)

|

±3/±10

|

|

|

Typical Spectral Bandwidth (FWHM

|

<3

|

|

|

Divergence (degree)(FWHM)

|

<3⊥< 10‖

|

|

|

Polarization

|

TE

|

|

|

Wavelength shift (nm/℃)

|

~0.28

|

|

|

Electrical Parameters

|

||

|

Working mode

|

QCW

|

|

|

Maximum Duty Cycle (%)

|

≤2%

|

|

|

Pulse Length (us)

|

50~1000

|

|

|

Frequency (Hz)

|

1~ 1000

|

|

|

Operation Current (A)

|

≤100~500

|

|

|

Operating Voltage (V)

|

≤ 2*N

|

|

|

Typical Slope (W/A)

|

> 1.1

|

|

|

Electro-optic Conversion Efficiency (%)

|

> 50

|

|

|

Thermal parameters

|

||

|

Operation Temperature (℃)

|

-40~60

|

|

|

Storage Temperature (℃)

|

-50~85

|

|

|

Storage humidity (%)

|

< 70

|

|

|

Cooling

|

TEC/Wind cooling

|

|

|

Flow rate per bar (L/min)

|

*

|

|

1. CIR QCW-MA-100~ -500-N represent N*100-500W laser stack which is mounted on an annular heat sink. The laser power of single bar is 100W, 200w, 300W and 500W.

2. The wavelengths of each bar in a single device can be arranged and combined according to the heat dissipation conditions.

3. The above parameters are measured at the heat sink temperature of 25℃.

4. Heat sink structure can be customized according to customer’s special requirements.

5. The duty cycle is usually less than 2%.In case of special high duty cycle requirements, the laser structure can be customized. Then duty circle up to 20%.

Reviews

There are no reviews yet.