Description

GCAN Efficient Control And Signal Processing PLC Controller

- Brand Name: MLHJ

- Place of Origin: Liaoning, China

- Brand Name: GCAN

- Model Number: GCAN-PLC-511

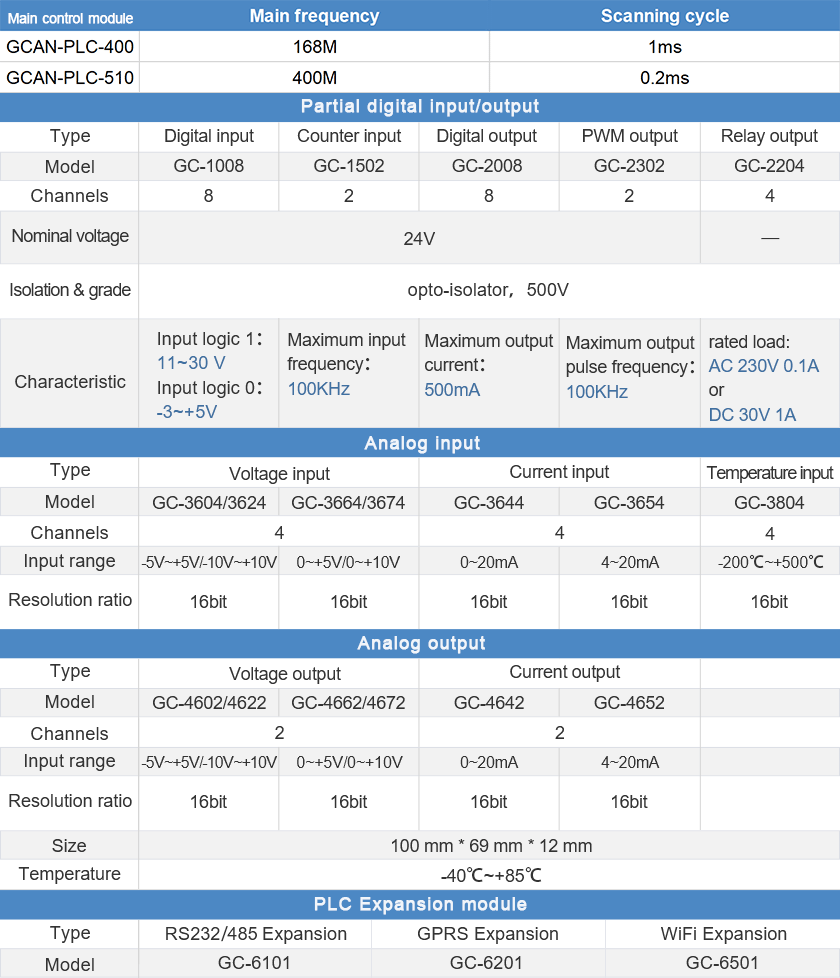

- Isolation level: Optocoupler isolation 500V

- CAN open baud rate(bps): 1000K,500K,250K,125K,100K,50K,10K

- PDO mode: synchronization, looping,event-driven, polling

- Bus terminal module quantity: up to 32 modules

- Digital I/O signal: 256 input/output

- Analog I/O signal: 64 input/output

- Configuration mode: automatic configuration

- PDO number (CAN open): 4Tx/4Rx

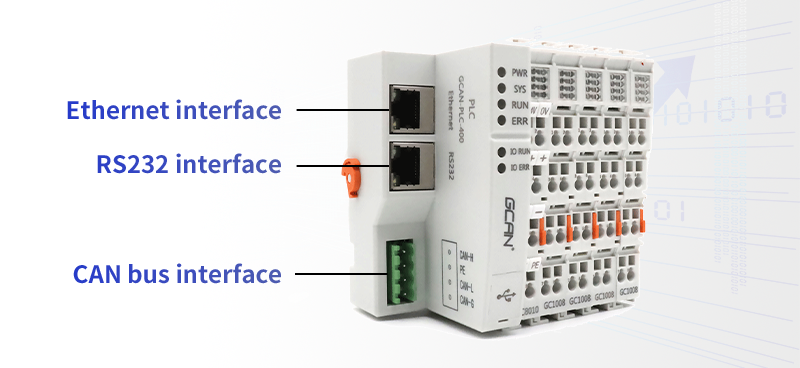

- CAN-Bus interface: one OPEN terminal interface,4Pin

- Power: 24V DC (-15% 20%)

Description

Total 3 control modules

Total 2 communication modules

Note: GCAN-IO-8000/8100 is not a PLC main control module, but a remote IO module. GCAN-IO-8000 is a CANopen adapter, and GCAN-IO-8100 is a Modbus RTU adapter.

Input and output modules

Product introduction

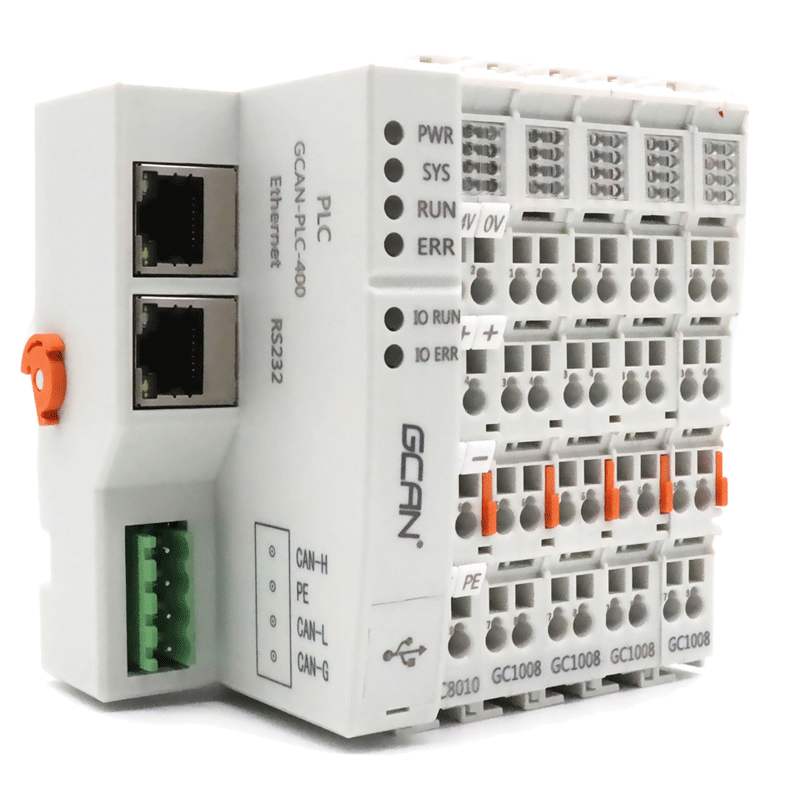

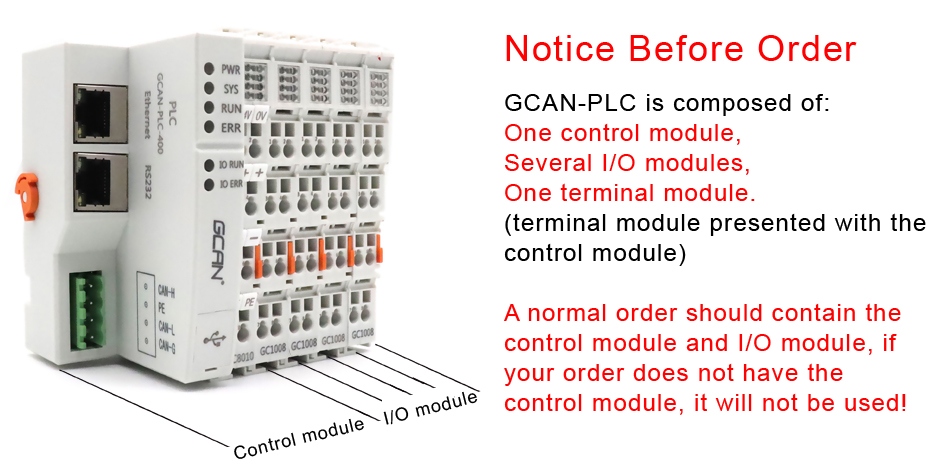

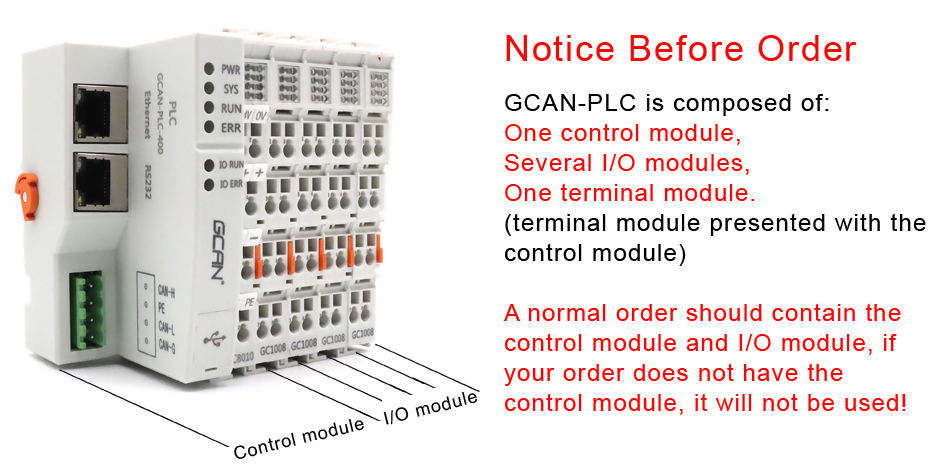

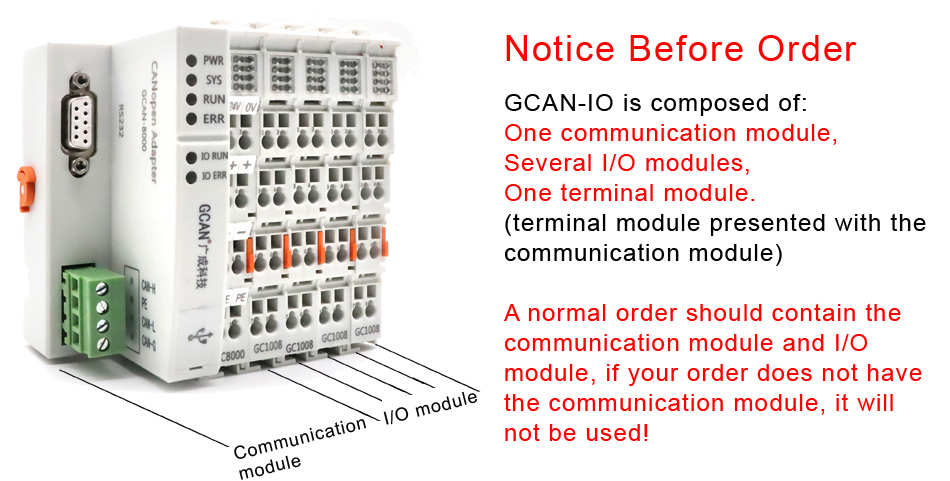

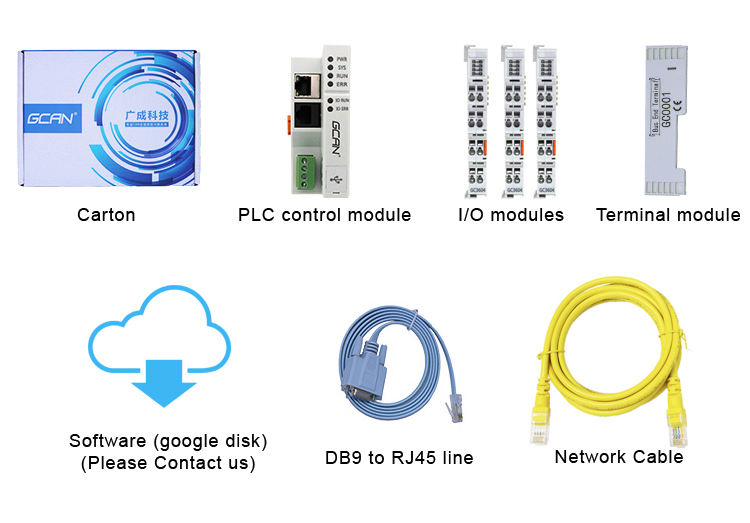

GCAN-PLC module is composed of a programmable control module (GCAN-PLC-400/510/511) and several I/O modules (GC-1008/2008/…). The control module uses high-speed CPU and has powerful computing and processing capacity. The control module also has a variety of fieldbus communication interfaces that users can use to connect to the corresponding network and communicate with other devices.

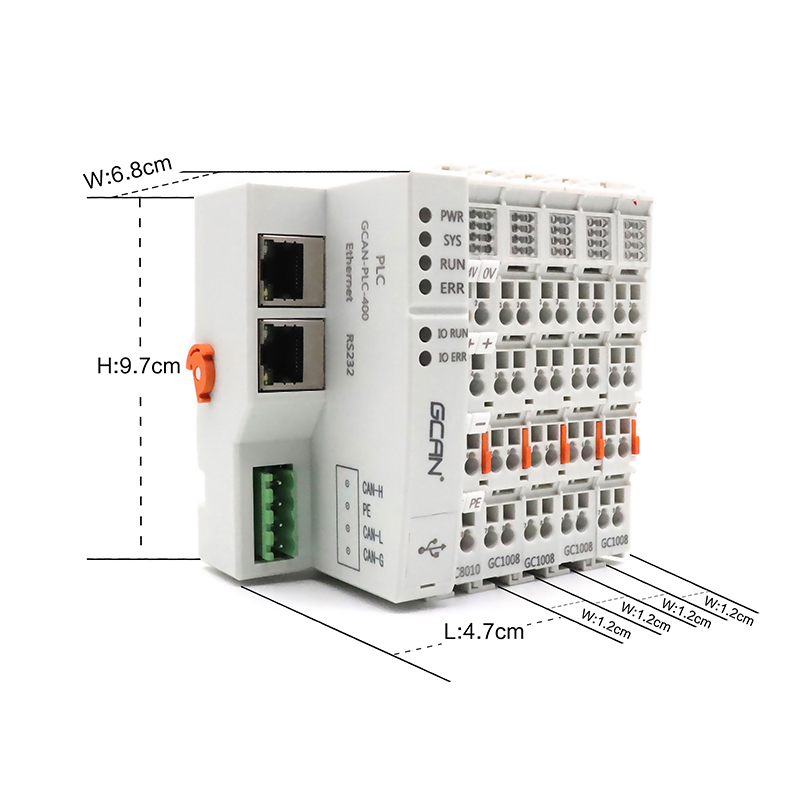

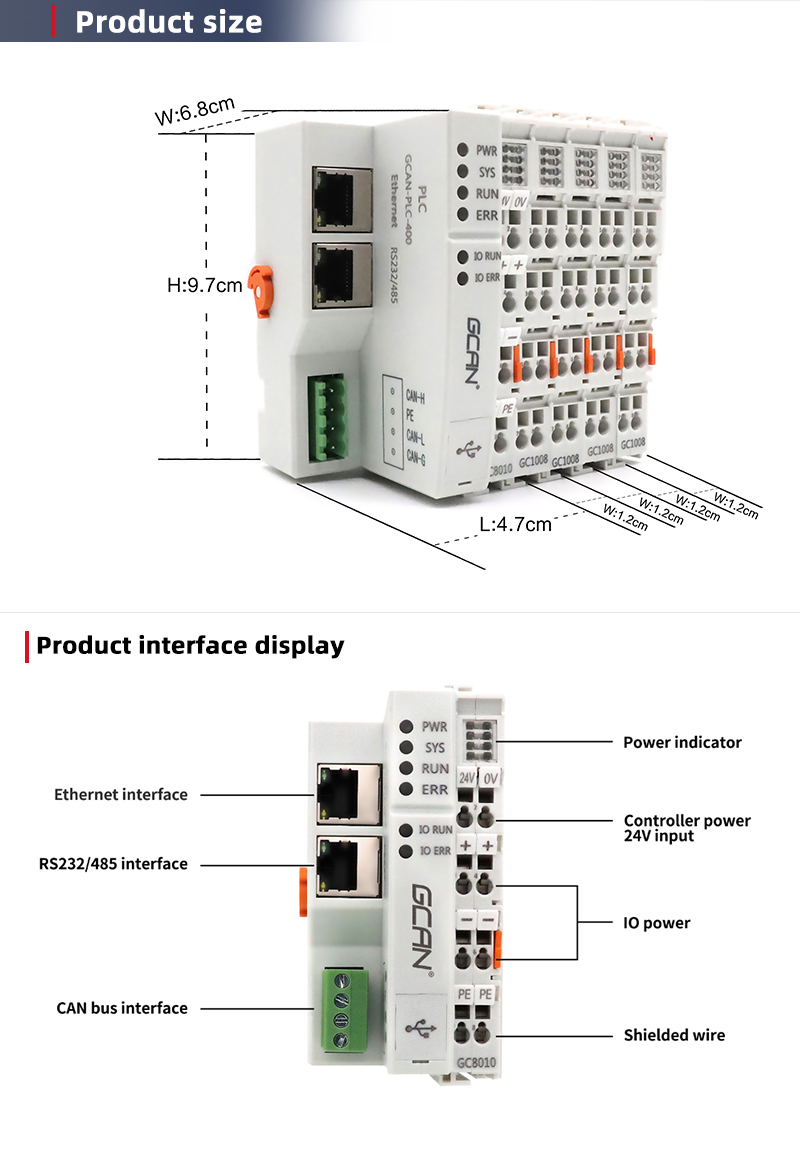

Product size

Product features

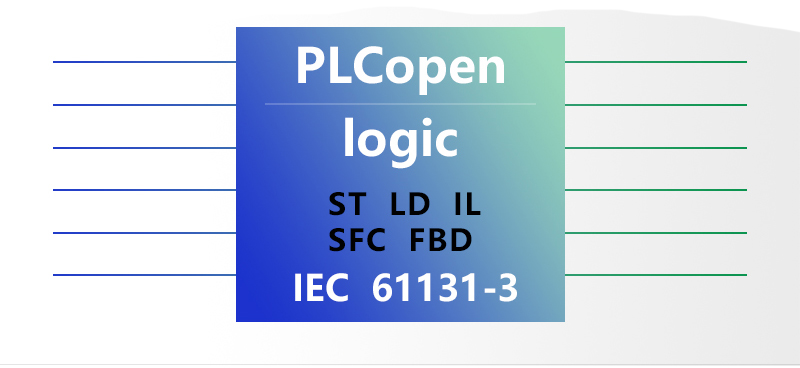

● CAN bus interface, with ISO11898 standard ● Ethernet interface, 10/100M adaptive ● Serial interface, RS232 or RS485 ● Programming: OpenPCS (support SFC, LD, FBD, ST, IL of IIEC 61131-3 standard) ● Power supply: 24V DC (18~36V) ● Maximum number of I/O modules to fit: 32 (up to 32*8 I/O points) ● Working temperature and humidity: -40°C~+85 °C, 0-95% RH without condensation ● Dimensions: 97 mm*68 mm*47 mm

Fast system response

GCAN-PLC series uses the German enbedded real-time kernel system,which not only has strong real-time performance and processing ability,but also supports users to program with the 5 programming languages specified in IEC 61131-3 standard,including SFC,LD,FBD,ST and IL.Flexible use of familiar programming languages can shorten the project development cycle.

Integrate three Interface

GCAN-PLC series has been integrated with RS232,Ethernet and CAN,three common industrial fieldbus communication interface,which can be programmed to realize the bus communication and networking.if users want to realize Modbus,CANopen and other communication protocols ,we will provide users with sample programs for their reference.

Extend IO number randomly

GCAN-PLC series can extend the amount of IO module according to the users actual needs.Up to 256 modules canbe extended.users can freely choose the type of IO,such as:analog quantity module,digital quantity module ,etc.GCAN-PLC series is very small size,users can extend a variety of functions in a compact space.Can meet the need of different customers.

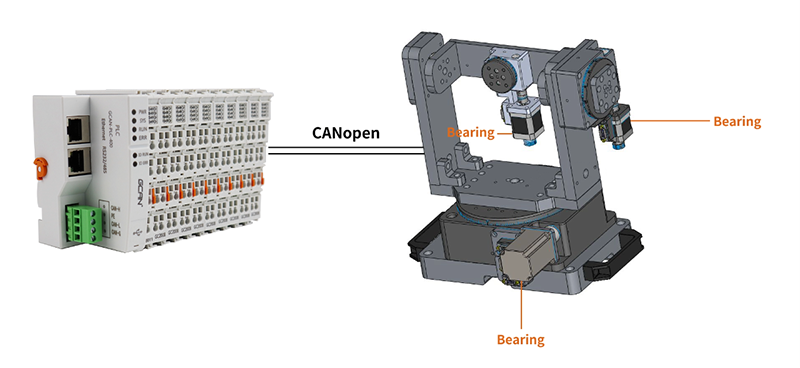

Applications

GCAN-PLC controls the servo motor through CANopen,and then controls the bearings through the servo motor to achieve mechanical control.

Through the key adjustment,LED working mode,and the output result are transmitted to the screen through Modbus for users to watch.

The computer sends data to the PLC remotely through the network(TCP),and the PLC sends pulses to control the motor work.

Packaging

our service

After-sale service

Our main products are all independent research and development.We provide one year free after-sales warranty,lifetime free software and technical support if you have any question,our after-sales engineer will answer for you,please feel free to purchase.

Factory

Certifications