Description

- Brand Name: OLOEY

- Item Type: UV GEL Curing Lamps

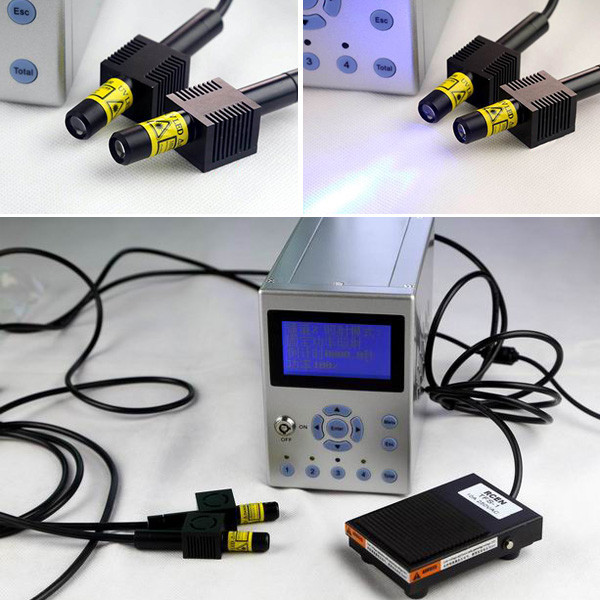

UV LED Spot Light Source Curing Machine Glue Dryer

Specifications of UV LED Irradiation machine Controller

The Number of Accessible Light Tip : 4

Host Size: L185 x W100 x H125mm

Terminal Blocks Input : Foot switch and RS-232 serial communication signals

Terminal Blocks Output : RS-232 serial communication signals

The host cooling way : Semiconductor natural cooling

Supply voltage : AC100-240V(50/60HZ)

Power consumed : 50W

Dimming / illumination control : Digital dimming, illumination control or manual timing control

Setting operation : Using the operating switch settings, power key switch, RS-232

External input : Enter irradiation alone, irradiation stop input, interlock, all light irradiation input switching varieties

External output : READY signal, error signal, warning output, BUSY output (each bald) add 5V output (indicator used)

The new UV LED spot light source curing system, through the power,light energy conversion makes LED high-power UV LED chips produced high purity 365nm monochromatic UV light, UV glue is highly concentrated in the energy required for curing wavelengths.

Application areas: electronics, precision parts, heads, optical lenses, LCD panels, micro-motors, medical supplies, crafts, fiber optic connectors, LCD, motors, hard drives and other emerging wide range of application areas can apply.

This product advantages:

1. Thermal radiation is small

This machine uses a light source of high-energy UV-LED 365nm, the conventional high pressure mercury lamp emitting illumination in different ways, which does not produce the infrared light source is a pure UV light, can not damage the parts in the case, the completion of the UV adhesive curing the bonding members with high accuracy. The machine uses the traditional UHP mercury lamp emitting ultraviolet light to illuminate the way, the illuminated surface temperature rise 95F-104F, while the use of LED UV exposure mode, the temperature rose only about 37.4F.

2. reduce production costs

(1) Due to this machine use LED luminous way, its life up to 25,000 hours (continuous ignition life) using energy-saving design, illuminated only when the need is lit, the actual life will be for more than 30,000 hours. Low power consumption of about 50W. (Conventional UV curing machine, typically 1000 hours lamp life, high power consumption, Power 30KW)

(2) LED Point Light fuselage small and lightweight, it can be easily integrated into automated assembly process, or as a complete desktop system can also be installed in a small device.

(3) LED light head through the computer control of the CPU, you can choose according to the actual needs of manual or automatic control operation, and the time required to set their own light irradiation (accurate to 0.01s) to further support the needs of high-precision engagement, reduce human operation time error.

(4) LED curing equipment almost no heat, non-friable, no mercury; do not demand maintenance costs (traditional curing lamp operating temperature is 932F, fragile, mercury, and high maintenance costs).

3. To improve work efficiency

UV-LED is equipped with a special condenser lens assembly also makes it highly concentrated energy on the solidification point, to enhance the efficiency of UV curing adhesive can be four (each device can be installed four LED tube) radiation while increasing the area .

4. Body compact, easy to operate

The machine uses ultra-small body, only the volume of the original high pressure mercury lamp irradiation machine 1/8, which makes this machine not only can be used for cell production line can also be installed in small devices, in order to be more convenient operation, irradiation from the first use leads the way on the back of the fuselage.

5. have 4 independently controlled irradiation head

Four independently controlled irradiation head can be applied to four independent stations require a single head output, reduce device configuration, while the four light head can also be programmed by a computer model to control the order of exposure, further support precision engagement requirement, reduce the time the human operator error.

Applications

UV glue curing

Experiments with ultraviolet light

Mineral composition testing

1 Main Unit